Understanding the Functions of Every Part in the Compound 3-Axis Transfer Stamping Line

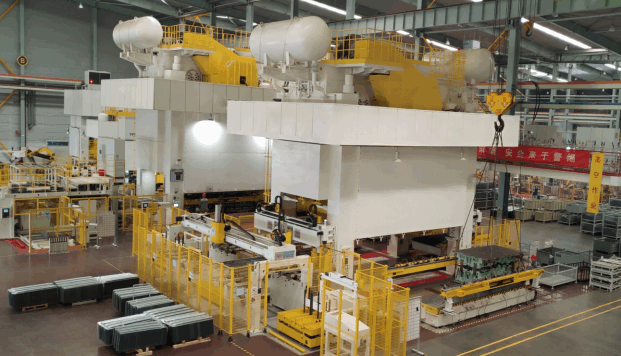

The compound 3-axis transfer stamping line is a multifunctional composite production line specifically designed to meet customer needs, integrating three-in-one progressive stamping and 3-axis multi-station stamping. It consists of NC straightener feeder, loading trolley, destacking manipulator, magnetic belt conveyor, 3-axis transfer, transfer bar, and exit conveyor. This production line integrates advanced automation control technology with an intelligent operating system, featuring high efficiency, high precision,