- [email protected]

- +86 138 2912 6172

[gtranslate]

We can provide design planning and solutions from whole plant and truly realize the turn-key project.

RUIHUI Intelligent Technology Co., Ltd. is a full-service supplier of stamping automation equipment, providing manufacturing machinery services and solutions to national and international industries since 2000.

We are committed to manufacturing the world’s best automation equipment for a wide range of industries including: automotive, medical devices, aerospace, 3C and appliance equipment. Learn what we can do for you to help jump start your idea!

The precision stamping process is an industrial process used to manufacture products with precisely defined surface contours. Types of precision stamping processes, such as progressive and double-action or conventional, deep-drawing, and flat-drawing, are applicable to the job, depending on the use of the part. Sheet metal blanks are molded with the help of punches having a shape corresponding to the desired part. The resulting components have sharp edges, flat surface finishes, excellent concentricity and dimensional accuracy. Precision stamping is very similar to the drop-drawing process, except that it does not involve upsetting operations and produces lightweight parts.

Precision stamping can be used in a wide range of applications, including electrical and electronic products, medical devices, test and measurement instruments, aerospace, energy, and automotive components. It can be used to manufacture electronic components and connectors, medical-grade prosthetics, instrumentation, communication antennas, and a variety of other applications.

The stamping process is widely used in many industries, and it is used in the majority of household appliances. Stamping is a high-efficiency manufacturing method with low material consumption. The stamping process is well suited to the production of large batches of parts, is easy to mechanize and automate, and has a high production efficiency. At the same time, stamping production cannot only strive for less waste and zero waste production, but it also has limited resources. The leftover material can also be used completely.

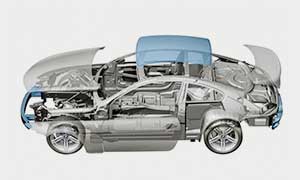

Automobile stamping refers to the metal stamping of automobile parts. Some automobile stamping parts become auto parts directly after stamping, while others must be processed by welding, machining, or painting before becoming auto parts after stamping.

Stamping, welding, painting, and assembly are the four major processes in vehicle production. The number of stamping parts of sheet metal parts is more than 40% of the more than 2,000 auto parts in industry statistics, and the status of stamping processing equipment in the automotive industry is critical. Today, the individual characteristics of automobiles accelerate the rate of model replacement. The model change is primarily reflected in the change of the body shape and structure, which is suitable for the ever-changing variety of sheet metal stamping parts.

Sheet metal stamping processes are one of the pillar processes in the manufacturing industry. The aerospace industry is one of the most important industries as it contributes to the development and advances in technology. It is estimated that the aerospace industry uses metals in greater amounts than the automotive and electrical industries combined.

Wings, fuselage, and all other support structures are some examples of sheet metal stamping parts that determine the safety and efficiency of both manned and unmanned aircraft in operation. Sheet metal stamping in the aerospace industry requires high accuracy with demanding tolerances, flexibility in terms of designs, strong and durable materials with desired material properties, cost-effectiveness with short turnaround times, fast production ramp-ups for different projects, and quality-focused procedures throughout the whole process

Want to learn more about how we can help your production facility? Need more information about our products and customizable options? Reach out to us today.