Features of the Laser Blanking Line and Its Applications in Various Fields

This project combines the working concepts of feeding blanking lines and laser cutting to solve the problem of rapid unloading of continuous metal and non-metal strips without molds, significantly reducing the investment in unloading equipment and mold consumption. The highly efficient optimized nesting software and multi-channel programming control software make the no-lapping cutting technology of the laser cutting […]

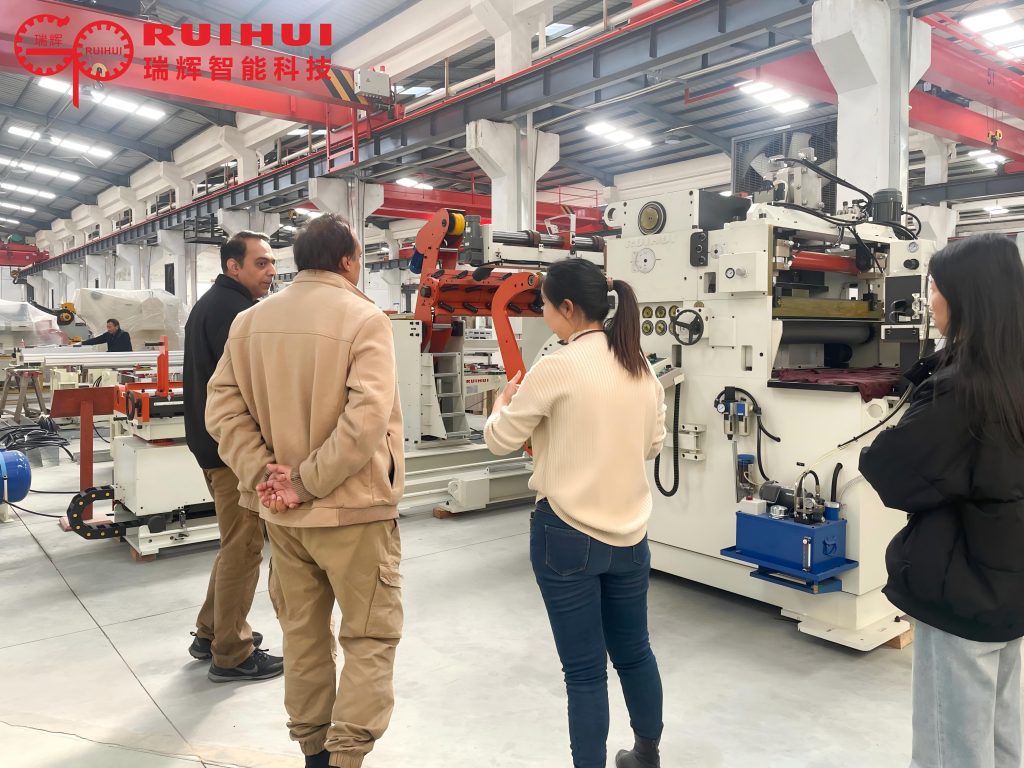

Indonesian Customers Visit Factory

Ruihui was honored to welcome an important customer delegation from Indonesia. The purpose of this visit is to gain a deeper understanding of our production process, technological innovation and product quality control system, and to further strengthen the cooperation and exchange between the two sides. Accompanied by the senior management of the company, the Indonesian […]

Every parts’ role of 3 IN 1 Strainghtener feeder

3 in 1 strainghtener feeder is a special machine which combined decoiler, strainghtener and feeder three parts into 1. This kind of machine can save a lot space in your factory at the same time the operation can become easier compared to buy these products seperately. Besides, according to your different sheet material, width, thickness […]

Watch the automation line up close and conduct technical exchanges in real time

SEE THE EQUIPMENT STRUCTURE UP CLOSE IN THE WORKSHOP On Juanuary 9, we took Pakistani customers around the factory and showed them the details of our 2-in-1 decoiler straighteners. VISIT THE CUSTOMER SITE TO SEE HOW THE AUTOMATION EQUIPMENT WORKS WITH THE PRESS On March 2, we brought Indian customers to our […]

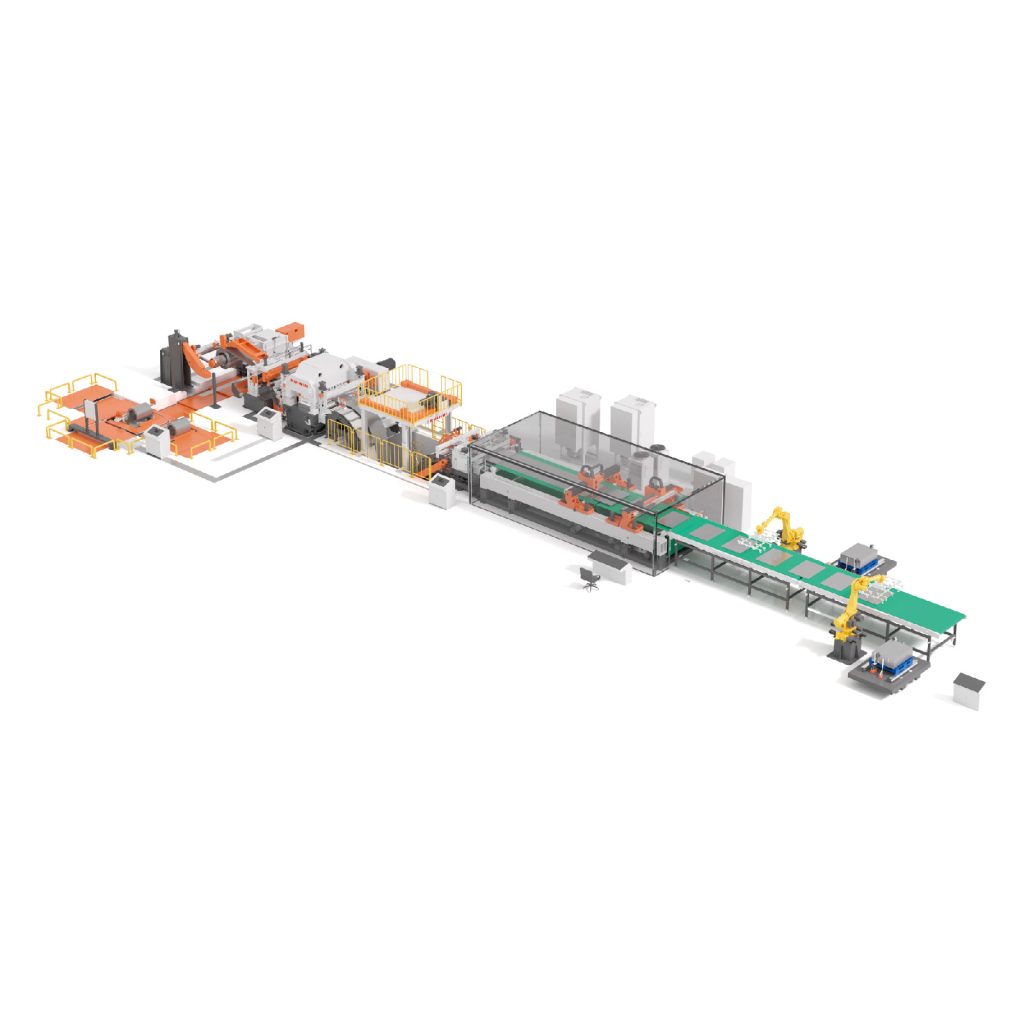

High-Speed Laser Blanking Line

High-Speed Laser Blanking Line Brand: RUIHUI Material Width: 1650mm/1850mm/2250mm Material Thickness: 0.6-3.5 (steel)/0.7-4.0(aluminum) Laser Cutting Machine Quantity: 2/3 Laser Power: 4/6kw X-Axis stroke: 1500mm/3200mm Y-Axis stroke: 1700mm/1900mm/2300mm Working Power Supply: Three-phase 380V/50Hz Email Inquire Linkedin Facebook Youtube Introduction This production line is suitable for the blanking process requirements of automotive plate parts, and has […]

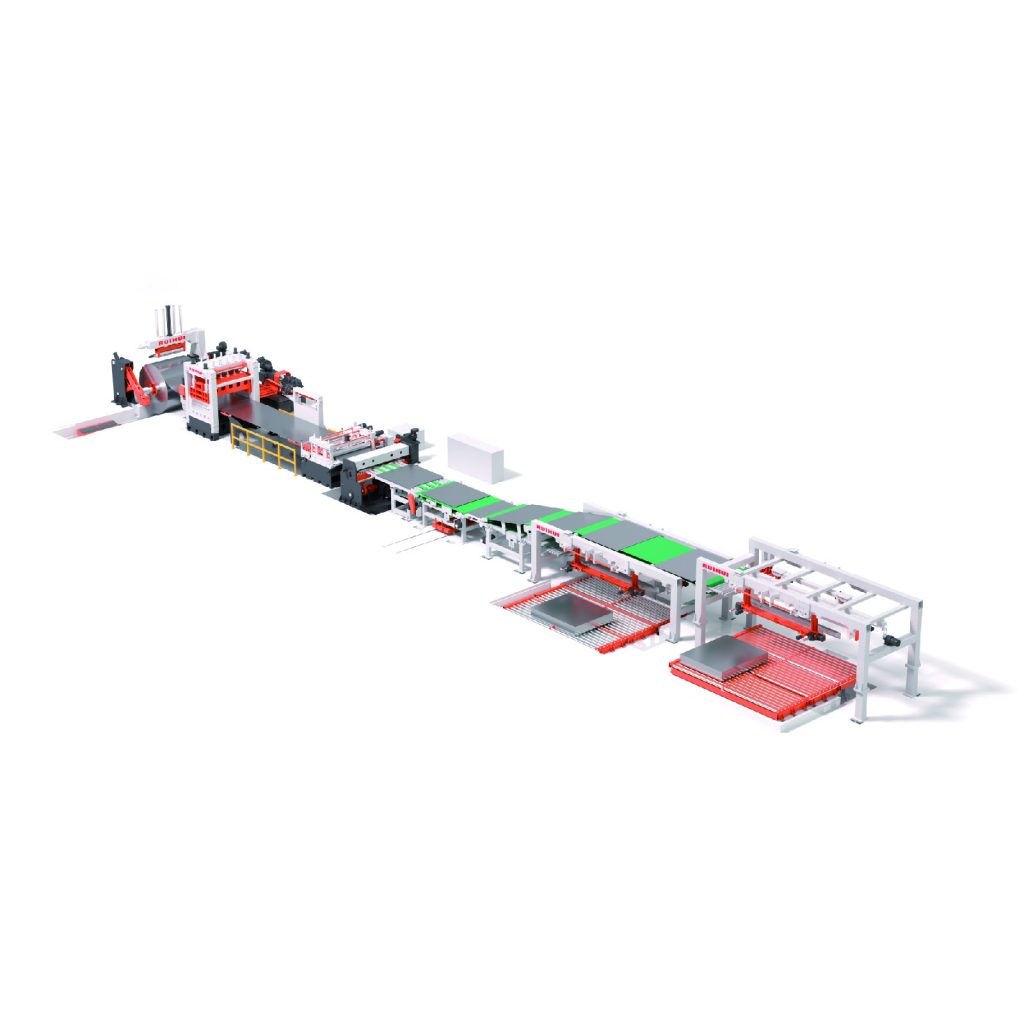

Cut to Length Production Line

Cut to Length Production Line Brand: RUIHUI Coil Weight: MAX 25T Material Width: MAX 2000mm Material Thickness: 0.4~4mm Belt Speed: 0~15m/min Shear Accuracy: ±0.5mm Shear Straightness: ≤0.1mm Average Capacity: 50000T/Y Email Inquire Linkedin Facebook Youtube Introduction This production line is equipped with precision leveling and servo-tracking shear functions to ensure that the finished products […]

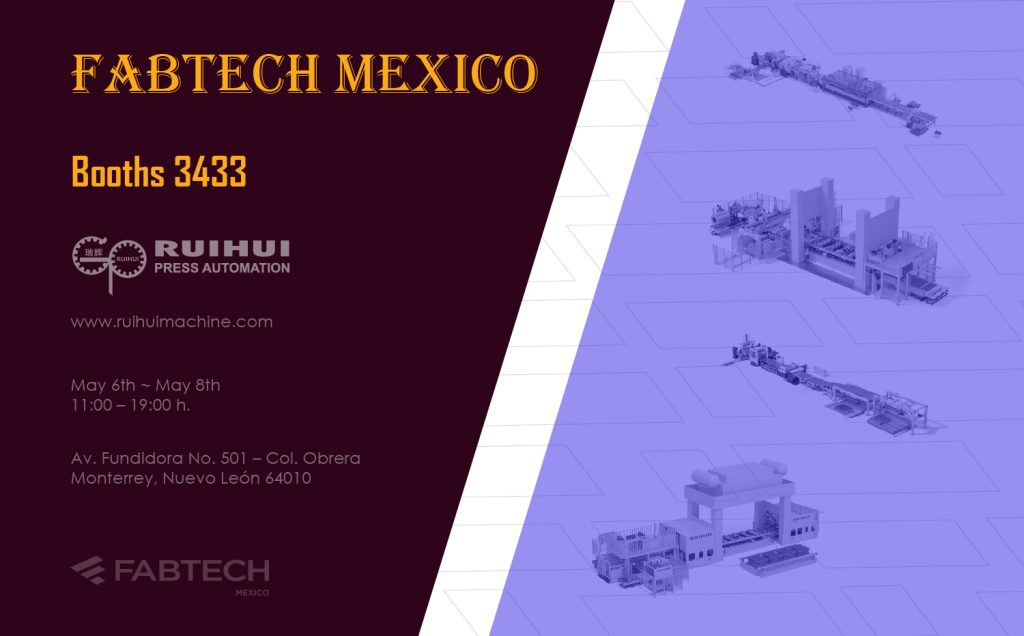

Ruihui will be attending FABTECH Mexico 2025 in May

We are excited to announce that Ruihui will be attending FABTECH Mexico, the leading metal forming, fabrication, welding, and finishing event in Latin America! Join us at Booth 3433 to explore our latest stamping automation solutions and technologies. 📍 Venue: Av. Fundidora No. 501, Monterrey, Mexico📅 Dates: May 6-8, 2025🕒 Time: 11:00 – 19:00 (May […]

What is a top suction type destacking multi-station manipulator stamping production line

The top suction multi-station manipulator stamping production line is a highly efficient automated production line, which is widely used. The production line integrates multiple key processes such as stack dismantling, transmission, and stamping. Through automated operation processes, it realizes efficient and accurate conversion from raw materials to finished products, greatly improving production efficiency and product […]

Understanding the two-in-one material rack straightening machine

In the field of modern metal processing, the precise processing of materials is a key prerequisite for ensuring product quality and production efficiency. However, in the initial stage of sheet metal processing, raw materials often have various forms of irregularities, such as bending, twisting and other problems, which greatly affect the accuracy and efficiency of […]

Equipped with a 3000T robot arm, the large coil slitting line is truly remarkable for several reasons

In the vast territory of the manufacturing industry, efficient and accurate production equipment has always been a powerful weapon for enterprises to seize the market highland. With the increasingly stringent requirements for product accuracy and production efficiency in various industries, traditional production equipment is gradually difficult to meet development needs. At this time, Guangdong Ruihui […]