Industry 4.0, the fourth industrial revolution, is transforming the manufacturing landscape. This transformation is fueled by technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and automation. One key component of Industry 4.0 is smart stamping automation, which is revolutionizing the stamping process.

Stamping is a vital manufacturing process that produces high-quality, precise metal parts for a wide range of industries, including aerospace, automotive, medical, and more. Stamping is a cost-effective way to produce complex parts in large volumes, making it a popular manufacturing technique. However, the stamping process can be time-consuming and require a high level of skill and expertise. Smart stamping automation aims to simplify and optimize the stamping process while maintaining high quality and precision.

In this article, we will explore smart stamping automation and its role in the Industry 4.0 transformation.

What is Smart Stamping Automation?

Smart stamping automation involves using advanced technology to automate and optimize the stamping process. The process involves feeding metal sheets into a stamping press, which then shapes the metal sheets into the desired shape using a die. The finished part is then removed from the press, and the process is repeated.

Traditionally, stamping has been a manual process that requires skilled workers to operate the stamping press and the die. This process is time-consuming and can lead to errors and inconsistencies in the finished parts. Smart stamping automation aims to overcome these challenges by automating and optimizing the stamping process.

There are several key components of smart stamping automation, including:

Robotic feeding systems:

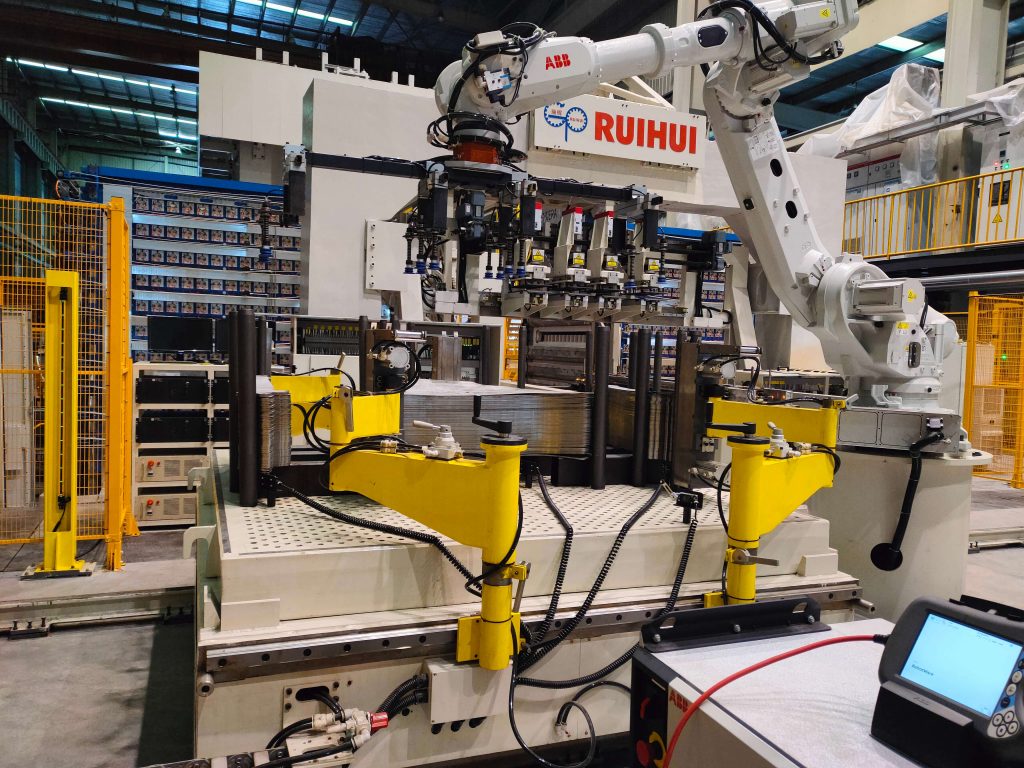

Robotic feeding systems are used to automate the process of feeding metal sheets into the stamping press. These systems use sensors and cameras to ensure that the metal sheets are positioned correctly and fed into the press at the right speed and angle. This reduces the risk of errors and inconsistencies in the finished parts.

Die recognition technology:

Die recognition technology uses sensors and cameras to recognize the shape and position of the die in the stamping press. This information is used to adjust the press’s settings and optimize the stamping process. Die recognition technology can also detect when a die needs to be replaced, reducing downtime and increasing efficiency.

Machine learning algorithms:

Machine learning algorithms can be used to analyze data from the stamping process and optimize the process in real-time. For example, machine learning algorithms can adjust the stamping press’s settings based on factors like the type of metal being stamped, the shape of the die, and the speed of the press. This can lead to faster production times, higher quality parts, and reduced waste.

Quality control systems:

Quality control systems are used to ensure that the finished parts meet the required quality standards. These systems use sensors and cameras to detect defects in the finished parts, such as cracks or deformities. The parts can then be sorted and rejected if necessary, reducing the risk of defective parts being shipped to customers.

Benefits of Smart Stamping Automation:

Smart stamping automation offers several benefits over traditional stamping processes, including:

Increased efficiency:

Smart stamping automation can significantly increase the speed and efficiency of the stamping process. Automated feeding systems, die recognition technology, and machine learning algorithms can all work together to optimize the stamping process and reduce downtime.

Improved quality:

Smart stamping automation can lead to higher-quality parts by reducing errors and inconsistencies in the stamping process. Quality control systems can also ensure that defective parts are detected and rejected before they are shipped to customers.

Cost savings:

Smart stamping automation can lead to significant cost savings by reducing labor costs and minimizing waste. Automated feeding systems can reduce the need for skilled workers, while machine learning algorithms can optimize the stamping process and reduce waste.

Smart stamping automation is a cutting-edge technology that has revolutionized the stamping industry. It involves the use of intelligent machines and software to automate the stamping process, resulting in increased efficiency, improved quality, increased flexibility, and faster production times.

Ruihui Intelligent Technology Co., Ltd. has more than 20 years of experience in the field of stamping automation. If you want to know more, please contact us!