Charming large coil turnover machine

As a large roll turning machine, it is obviously used to flip large rolls. It consists of loading and unloading parts and a turning part. This kind of turning machine is usually used in the metal processing industry, such as steel mills and non-ferrous metal processing plants. In these factories, large rolls need to be […]

Unveiling the Uncoiling and Straightening Machine

In the modern metal processing industry, the uncoiling and straightening machine has become an indispensable key equipment for many enterprises due to its high efficiency and accuracy. It integrates uncoiling and straightening functions, and can continuously process coils of metal sheets, effectively improving production efficiency and product quality. Main function standard accessories Specifications model RGL-200 […]

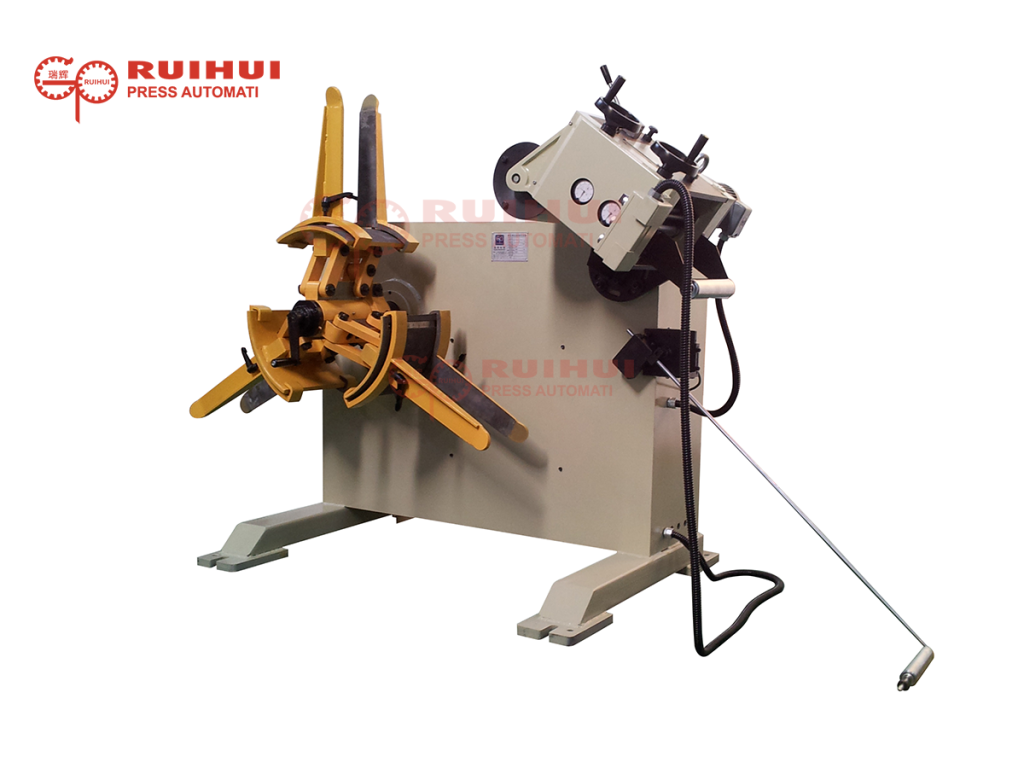

Heavy-duty uncoilers and double-head material racks

In the metal processing industry, efficient and accurate material handling equipment is the key to ensuring a smooth production process and stable product quality. Heavy-duty uncoilers and double-headed material racks are the core equipment in the initial stage of metal coil processing, and their performance directly affects the efficiency and accuracy of subsequent processing. In-depth […]

Precision leveling machine RLF series

In the field of modern precision parts processing, the flattening process of sheet materials is a key link to ensure product quality. Ruihui Automation’s RLF series precision leveling machine, with its excellent performance and advanced technology, has become a rational choice for many processing enterprises. Precise design to meet diverse needs The RLF series supports […]

Let’s learn about the translational robot arm that can produce efficiently and the series stamping of the translational robot arm

In today’s highly competitive industrial field, efficiency and accuracy are the keys to a company’s foothold. Guangdong Ruihui Intelligent Technology Co., Ltd.’s translation robot arm is bringing new changes to major production enterprises with an innovative attitude, leading the industry to a new era of efficient production. Working principle: The translation robot arm is composed […]

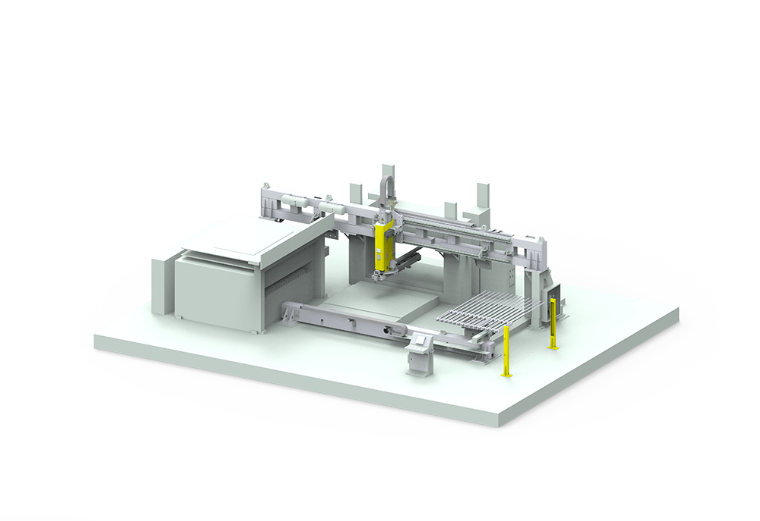

Large uncoiling blanking line at the core of industrial manufacturing

In the vast territory of modern industrial manufacturing, the large uncoiling blanking line is like a silent hero behind the scenes, playing a crucial role. It is a key link in the sheet metal processing process and is widely used in automobile manufacturing, home appliance production, aerospace and many other fields, providing a solid guarantee […]

Indispensable magnetic belt

In the field of industrial production, the efficiency and stability of the transmission system is crucial. Guangdong Ruihui Intelligent Technology Co., Ltd. focuses on intelligent technology Product Research & Development. Our magnetic belts bring better transmission solutions to various industries with innovative technology and excellent performance. Today, we will introduce the expertise of magnetic belts […]

Unveil the conveyor stack

In today’s highly competitive global manufacturing and logistics industry, efficient and accurate material handling and storage are key factors for enterprises to enhance their competitiveness. Conveyor stacking systems are playing an increasingly important role as an important means to realize the automated flow and storage of materials. Guangdong Ruihui Intelligent Technology Co., Ltd. has provided […]

What is Hot Forming Process Testing Line

The Hot Stamping Process Test Line is an integrated test system that combines various equipment and technologies to simulate and analyze the entire hot forming production process under controlled conditions. The Main Goal of hot forming process inspection line The main goal of this product is to evaluate the properties of the material during the […]

Key Features of Servo roller feeder in stamping automation

In the field of stamping automation, the servo roller feeder has always played a crucial role, not only improving production efficiency, but also ensuring product quality. Our company’s RNC series servo roller feeder has such advantages, providing strong support for the stamping production of many enterprises. I. Diverse Specifications to Meet Diverse Requirements The RNC series includes […]