Feeder machines are essential in various industries to automate material handling and transportation. There are several types of feeder machines, each with unique features and capabilities. the industry of automatic feeders is also very mature, today we will talk about automatic feeders.

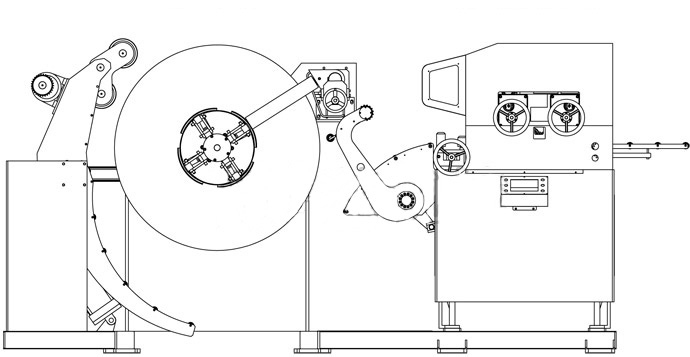

The automatic feeder adopts a unique mechanical and electrical structure and is equipped with fully automated numerical control The control system uses the principle of the servo motor to drive the feeding roller to efficiently and automatically feed the material.

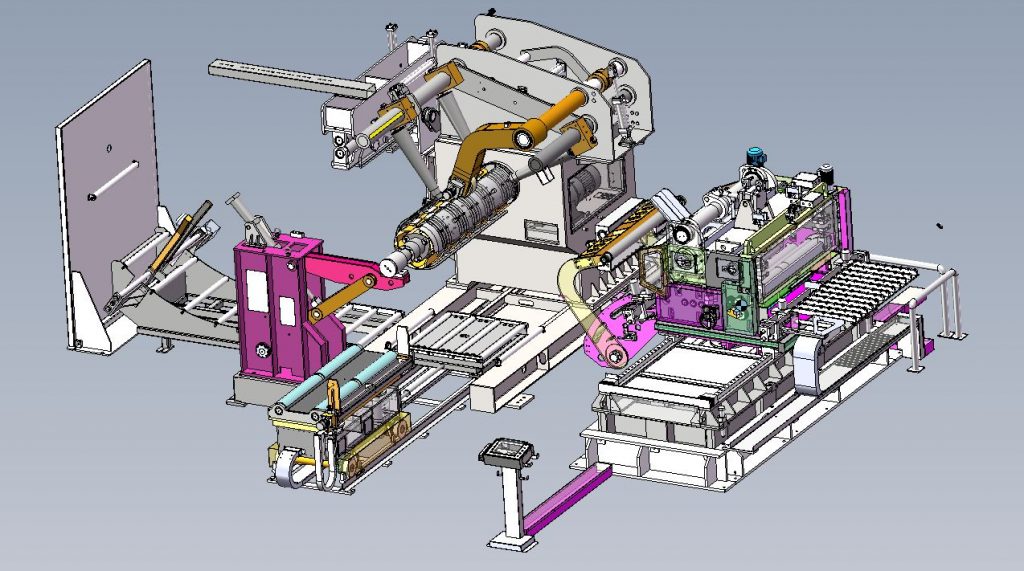

Its application is mainly utilized for fully automatic feeding of medium and thick plate coils. It is often equipped with uncoiling and leveling machinery. With the continual advancement of customers’ need for automated, efficient, and high-precision stamping production, faultless uncoiling and blanking, and leveling materials from feeding to stamping, the three-in-one feeder was developed, which is more favorable to stamping on thick plates.

Until now, customers’ preferred automation equipment has been three-in-one feeder mechanical equipment, which is gradually replacing traditional split automation equipment and becoming the mainstream equipment in the stamping market.

There are many types of feeders machines. When selecting, it is necessary to provide accurate material parameters to the feeder machinery manufacturer, so that the feeder machinery manufacturer can recommend suitable products.

Pneumatic NC Servo Feeder:

This is the most commonly used servo feeder model in the stamping industry. It adopts cylinder clamping and loosening, which is not restricted by installation.

It can not only be used with almost all punching machines but also with hydraulic presses and shearing machines.

There are two models of 0-2.2mm and 0-3.2mm to choose from, but due to the use of cylinder push-pull to relax, there is a certain response time, so it is not suitable for high-speed feeding occasions.

Mechanical NC Servo Feeder:

Its relaxation method adopts the mechanical rod to relax, the relaxation speed is fast, and the installation is limited. It is mainly used with a punch press for short-step high-speed feeding.

There are also two types of machinery: 2.2mm and 3.2mm. Thickness models are available, it is easier to relax and debug, and it is recommended for occasions where both mechanical NC and pneumatic NC can be used.

Thick plate NC servo feeder:

It is a specially developed model for conveying 4.5mm thick plates. Compared with ordinary NC servo feeders, it not only increases the power of the motor and the angle between the upper and lower gears of the feeding drum.

In addition, a pair of feeding rollers are added, which fundamentally eliminates the phenomenon of slippage and unstable precision in the conveying of thick plate materials.

Thick Plate Strong NC Servo Feeder:

It is a feeding model specially developed and produced for high-tension thick plates. It can convey 600N/mm2 plates that cannot be conveyed by traditional feeders.

Compared with the thick plate type, the transmission is changed. In this way, the direct transmission type of the traditional servo motor through the synchronous pulley is changed to the transmission type of the servo motor through the reducer, thus ensuring sufficient power for the conveying of high-tension thick plates.

Machine and electronic control integrated NC servo feeder:

Machine and electronic control integrated NC servo feeder is a high-precision and efficient feeding system that can be used in a variety of manufacturing processes, such as stamping, punching, and forming. It helps to increase productivity and reduce material waste by ensuring that the material is delivered to the manufacturing machine accurately and consistently. It is a new type of machine specially developed to save space and simplify the operation process.

Oscillating NC Servo Feeder:

It is a model designed specifically for the processing and production of wafer blanking customers. It is driven by one set of Mitsubishi PLC and two sets of servo motors and five buckets (there are two options for Mitsubishi and Yaskawa ). to realize the conveying of materials on the two-dimensional plane, so that the blanking of the wafers can reach the mutual tangent of circles, and maximize the utilization rate of materials.

Ruihui is a stamping automation equipment manufacturer with more than 20 years of experience. The company is committed to providing customers with high-quality, high-efficiency automation equipment solutions, and has won a good reputation in the industry.

The company’s core products include feeders, levelers, uncoilers, 3-in-1 feeders, blanking lines, composite multi-station equipment, manipulators, thermoforming and other automation equipment. These devices are widely used in the production lines of automobiles, electronics, home appliances, hardware and other fields, which can help enterprises improve production efficiency, reduce labor costs, and improve product quality.

The company has a professional R&D team and strict quality control system to ensure the leading technology and reliable quality of products. In addition, the company also provides customized solutions and after-sales services to meet the different needs and requirements of customers.

If you want to know and purchase stamping automation equipment, please contact us. looking forward to your cooperation.