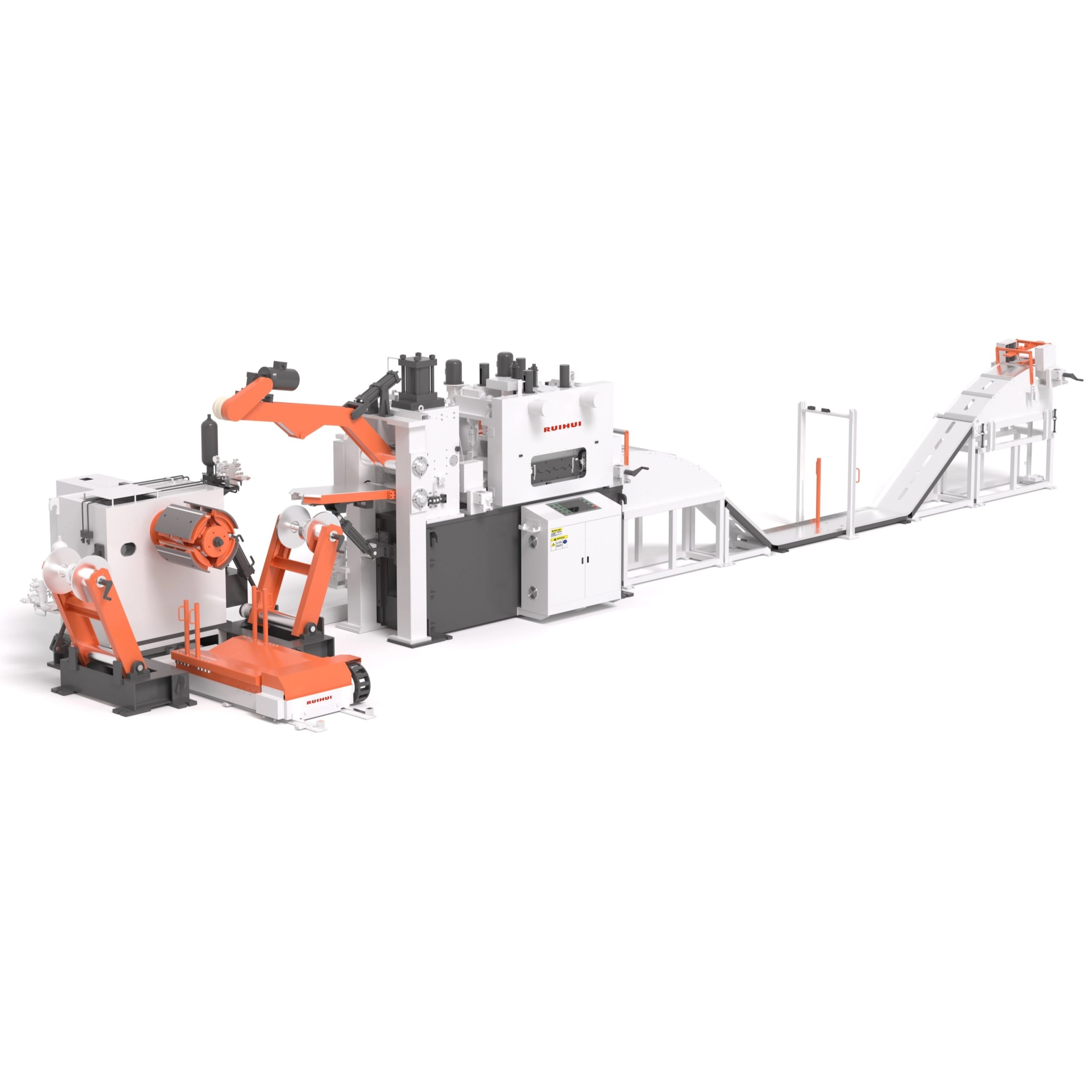

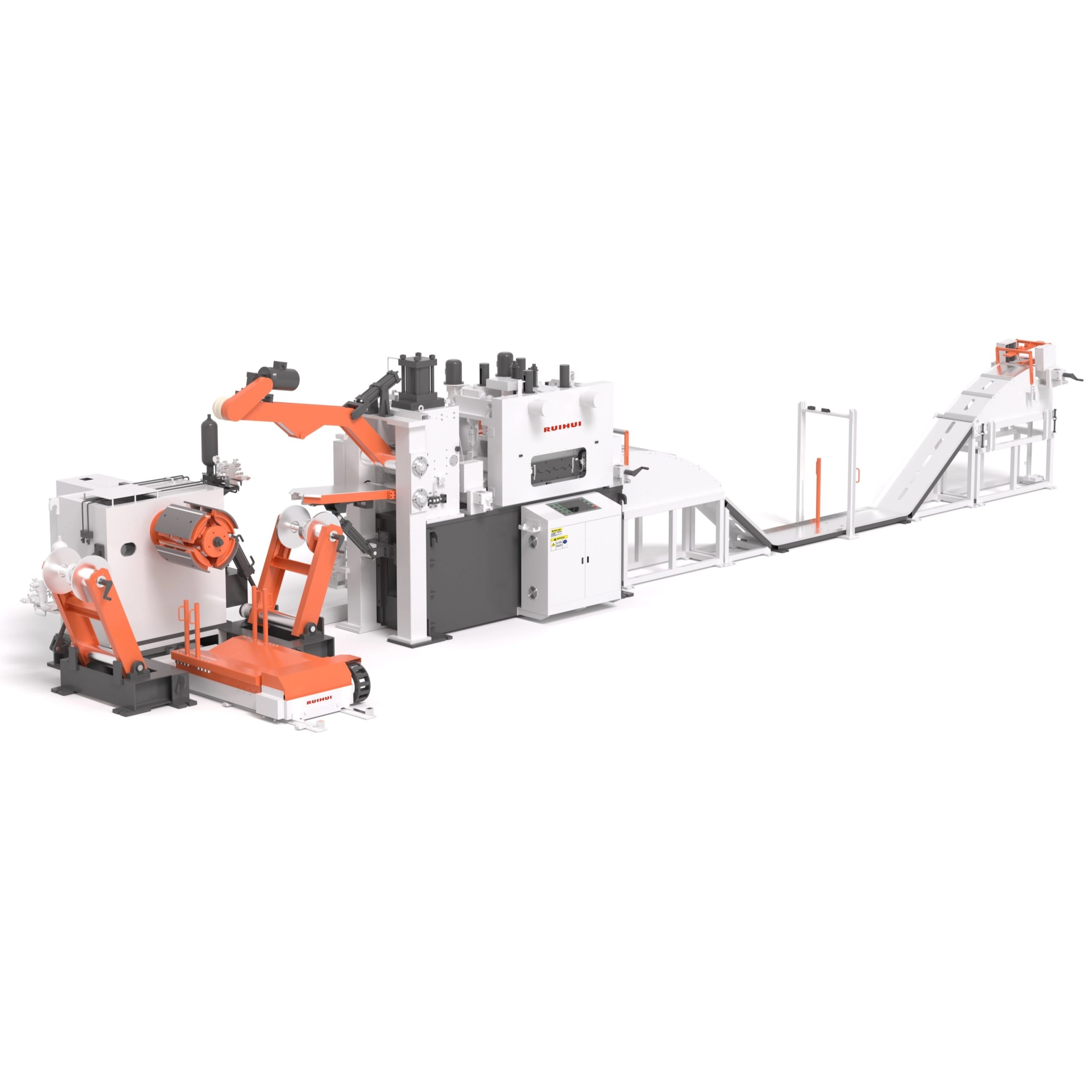

SMAC3 Intelligent Feeding Line

SMAC3 Intelligent Feeding Line Coil Width (mm): 70-500 Coil Thickness (mm): 1.0-3.0 Coll I.D. (mm): Φ508 Coil O.D. (mm): Φ800-Φ1500 Max Coil Weight (kg): 8000

Model: MAC5

Category: 3-in-1 Machine

Brand: RuiHui

Material width(mm): 100-1300

Material Thickness(mm): 0.8-9

Speed(m/min): 22

Supply Ability: 20 set / Month In Stock!

Payment Terms: T/T

It is especially suitable to match with an S-type leveler, gear feeder, and high-speed punching machine to form a high-speed synchronous stamping line for the motor stator and EI piece.

3-in-1 automatic feeding device integrating feeding, straightening and the material rack is high-tech, high-precision, high-efficiency, and has a particularly good effect on extra-long, extra-wide, and thick materials. It is unanimously regarded as an advanced automatic feeding device in the industry.

Uncoiler Straightener Feeder 3-in-1 machine is mainly used for straightening materials with a thickness of 0.8~9.0mm. Generally, 9 sticks are used for the stick system. At present, the maximum width of the corresponding material is 2000mm. The upper part of the roller is tilted upward by 20 degrees, which is convenient for cleaning the surface of the leveling roller, such as oil stains, waste chips, non-ferrous metal oxide layers, etc. The stability is mainly used for stamping auto parts.

1. MAC5 3-in-1 uncoiler straightener feeder is generally used in the auto parts industry. There are many first- and second-tier auto parts suppliers and the maximum width is currently 2000mm;

2. According to the thickness of the material, generally this model is equipped with a punch of 800T or more.

3. It is used for materials with high tensile force above 613MPA.

4. This model can be customized with a leveling structure opening device; the material yield strength can reach more than 613MPA.

5. It integrates uncoiling, leveling, feeder, and cutting into one, which is easy to operate and occupies a small area.

6. Adopt a servo system imported from Japan to ensure high-precision feeding.

7. This model machine is all customized models.

| Model | MAC5-600H | MAC5-800H | MAC5-1000H | MAC5-1300H |

| Stock Width(mm) | 100~600 | 100~800 | 100~1000 | 100~1300 |

| Stock Thickness(mm) | 0.8~9.0 | 0.8~9.0 | 0.8~9.0 | 0.8~9.0 |

| Max.Coil Weight(kg) | 5000 | 7000 | 10000 | 10000 |

| Max.Coil O.D.(mm) | Φ1400 | Φ1400 | Φ1400 | Φ1400 |

| Coil I.D.(mm) | Φ508 | Φ508 | Φ508 | Φ508 |

| Feed Length(mm) | 0~500 | 0~500 | 0~500 | 0~500 |

| Max.Line Speed(m/min) | 22 | 22 | 22 | 22 |

| Work Roll Number | Upper 5/Lower4 | Upper 5/Lower4 | Upper 5/Lower4 | Upper 5/Lower4 |

| Feed Roll number | Upper 1/Lower1 | Upper 1/Lower1 | Upper 1/Lower1 | Upper 1/Lower1 |

| Main Motor(kw) | AC22 | AC22 | AC30 | AC30 |

| Mandrel Expansion | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Reel Mot or(kw) | 5.5 | 7.5 | 11 | 22 |

| Power (V) | AC380/50HZ | |||

| Operating Air(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 |

| Model | MAC5-600H | MAC5-800H | MAC5-1000H | MAC5-1300H | |

Stock Width | 0.8 | 600 | 800 | 1000 | 1300 |

| 1.4 | |||||

| 1.6 | |||||

| 1.8 | |||||

| 2 | |||||

| 2.3 | |||||

| 2.8 | |||||

| 3.2 | 1030 | ||||

| 4 | 800 | 800 | |||

| 4.5 | 648 | 648 | 720 | ||

| 5 | 530 | 530 | 530 | 648 | |

| 6 | 450 | 450 | 450 | 530 | |

| 7 | 331 | 331 | 331 | 450 | |

| 8 | 253 | 253 | 253 | 331 | |

| 9 | 200 | 200 | 200 | 253 | |

1. Strong water resit bottom in plywood.

2. Corner protect by foam and fixed by a protective film.

3. All covered by a strong and hard protective film.

4. Inside steel frame protector.

5. Plywood packing and steel strip outside fixed the box.

6. Finishing packing by normal container or frame container.

1. Equipment model selection, provide the technical parameters of the relevant equipment.

2. Progressing Solution Design: According to the customer’s product processing requirement, we can design a unique solution that supports higher manufacturing efficiency and better processing quality for the customer.

3. Customized Machine Design: According to the customer’s application, we may revise our machine according to the customer’s convenience and high production efficiency.

1. As a professional Automation machine manufacturer and supplier, RUIHUI will supply the all machine with training video and user’s manual in English for installation, operation, maintenance, and trouble-shooting, and shall give technical guides by remote, such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will offer professional guidance and direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools, and a testing facility. Training Time: 3~5 days.

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses, and accommodation to us during the business trip and service period before their dispatch.

As a top Automation Machine brand in the world, RUIHUI promise:

1. 1 year for the whole Ruihui machine free warranty.

2. Long life-time maintenance, the after-sale department will offer 24/7 English online support.

3. We provide machine-related parts service

4. After the warranty period expired, the Ruihui buyer only needs to pay the actual maintenance cost.

5. Certificate support:

All the machines can be shipped worldwide by sea, air, or express logistics via DHL, FedEx, and UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

SMAC3 Intelligent Feeding Line Coil Width (mm): 70-500 Coil Thickness (mm): 1.0-3.0 Coll I.D. (mm): Φ508 Coil O.D. (mm): Φ800-Φ1500 Max Coil Weight (kg): 8000

MAC1 Uncoiler Straightener Feeder Machine For Thin Plate Model: MAC1 Category: 3-in-1 Machine Brand: RuiHui Material width(mm): 50-400 Material Thickness(mm): 0.2-3.0 Speed(m/min): 16-24 Supply Ability: 20 set

MAC2 Decoiler Straightener Feeder Machine 3-in-1 Model: MAC2 Category: 3-in-1 Machine Brand: RuiHui Material width(mm): 50-800 Material Thickness(mm): 0.3-3.2 Speed(m/min): 16-24 Supply Ability: 20 set / Month

MAC3 Uncoiler Straightener Feeder Machine 3-in-1 Model: MAC3 Category: 3-in-1 Machine Brand: RuiHui Material width(mm): 50-1000 Material Thickness(mm): 0.3-4.5 Speed(m/min): 16-24 Supply Ability: 20 set / Month In