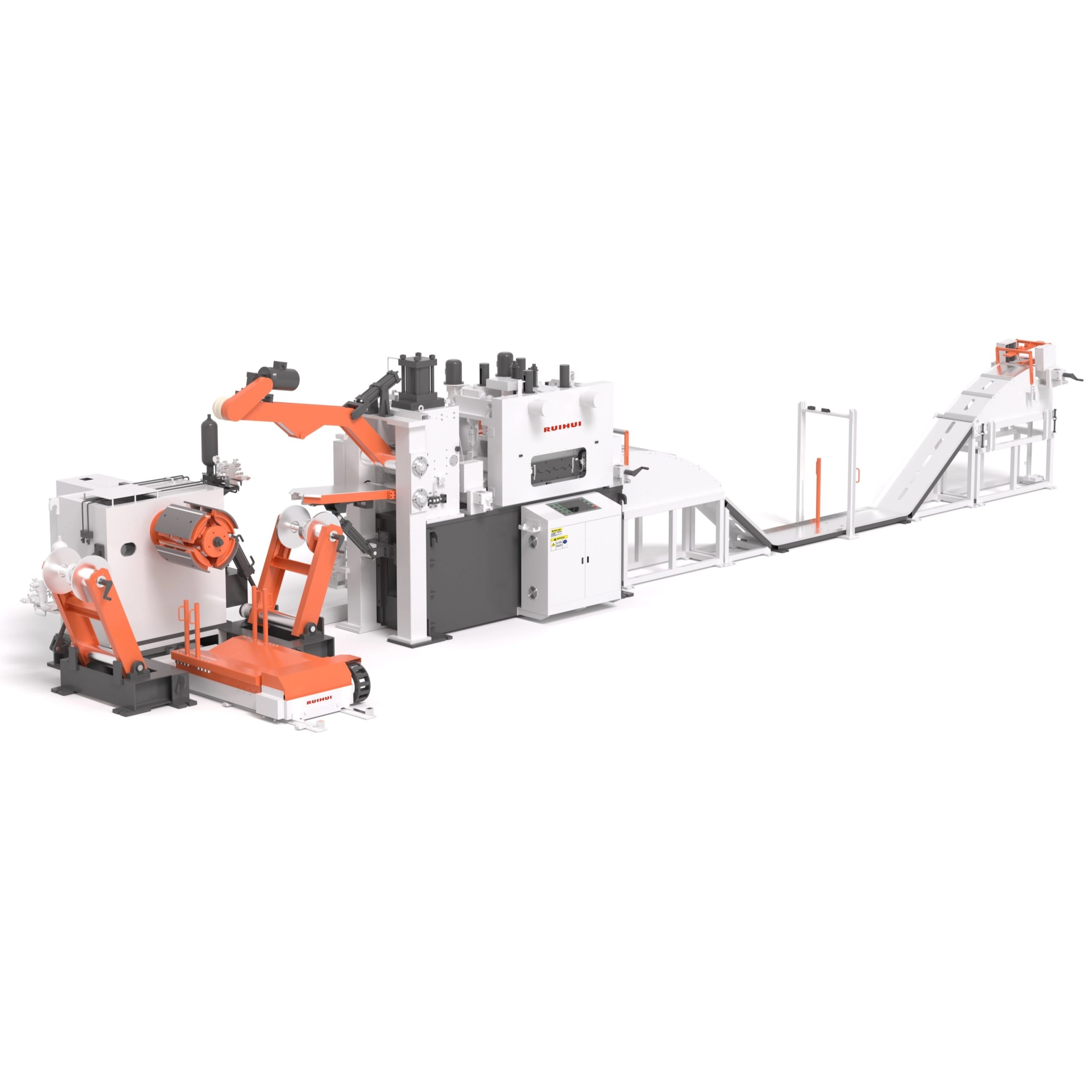

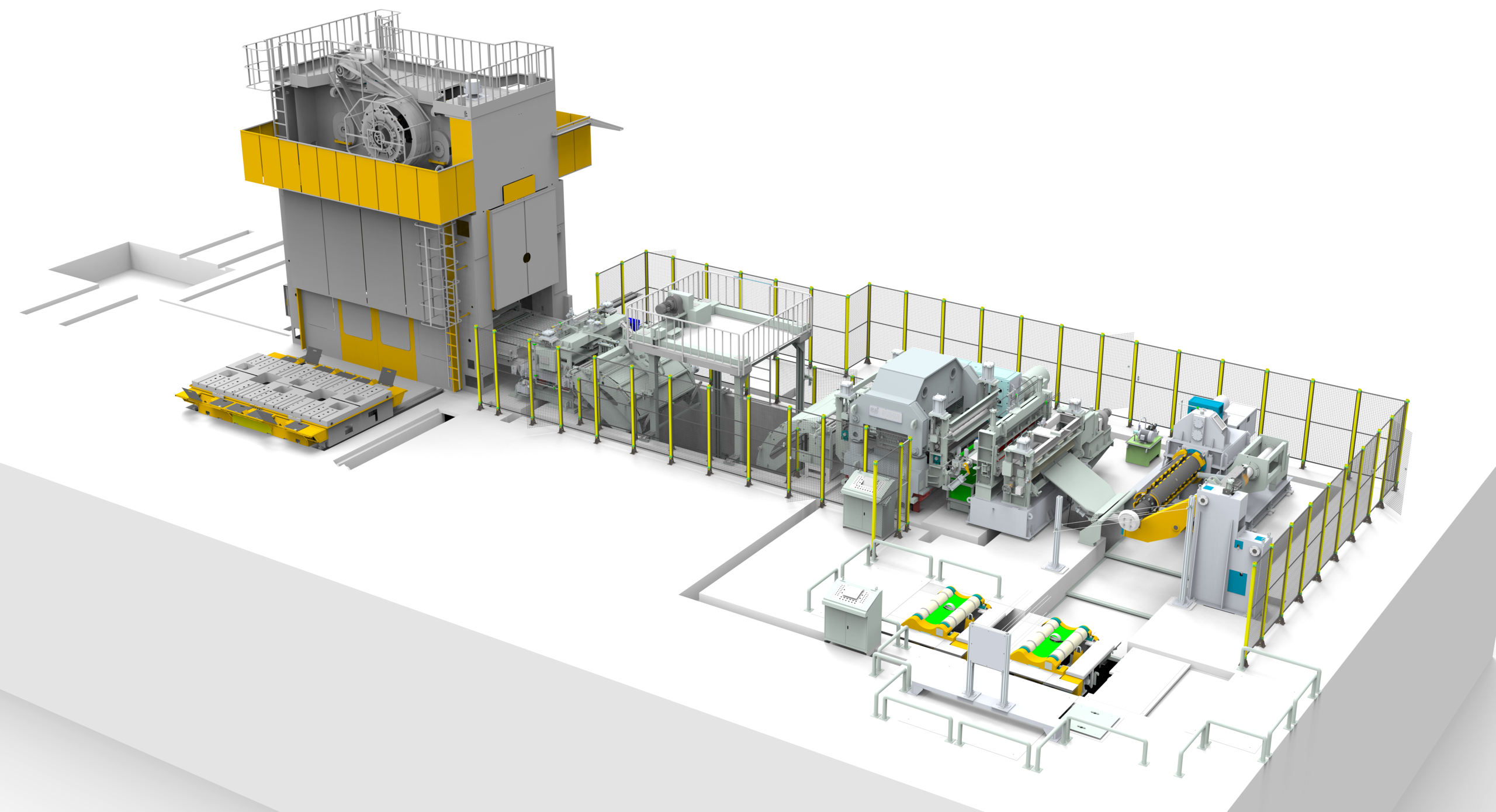

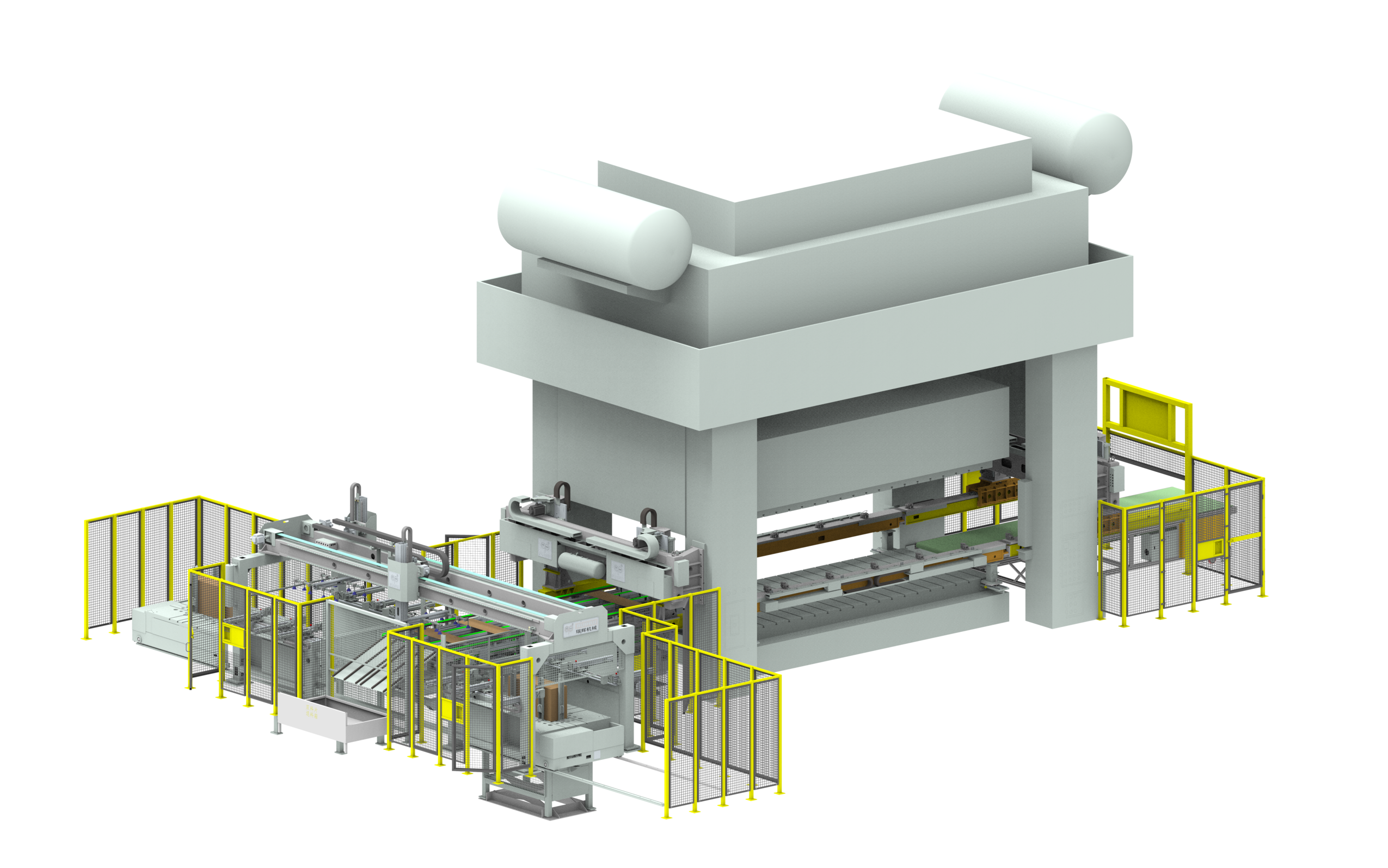

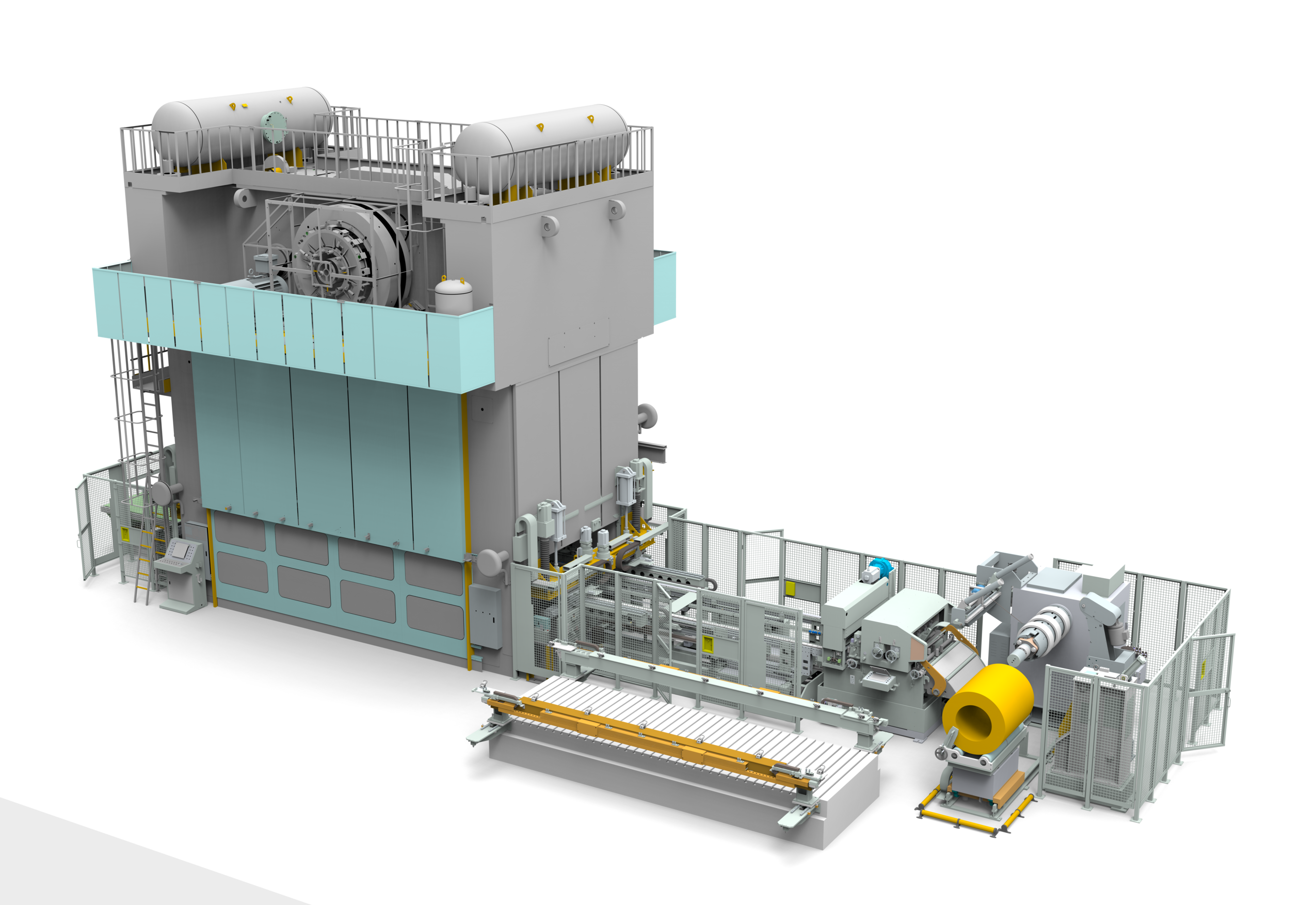

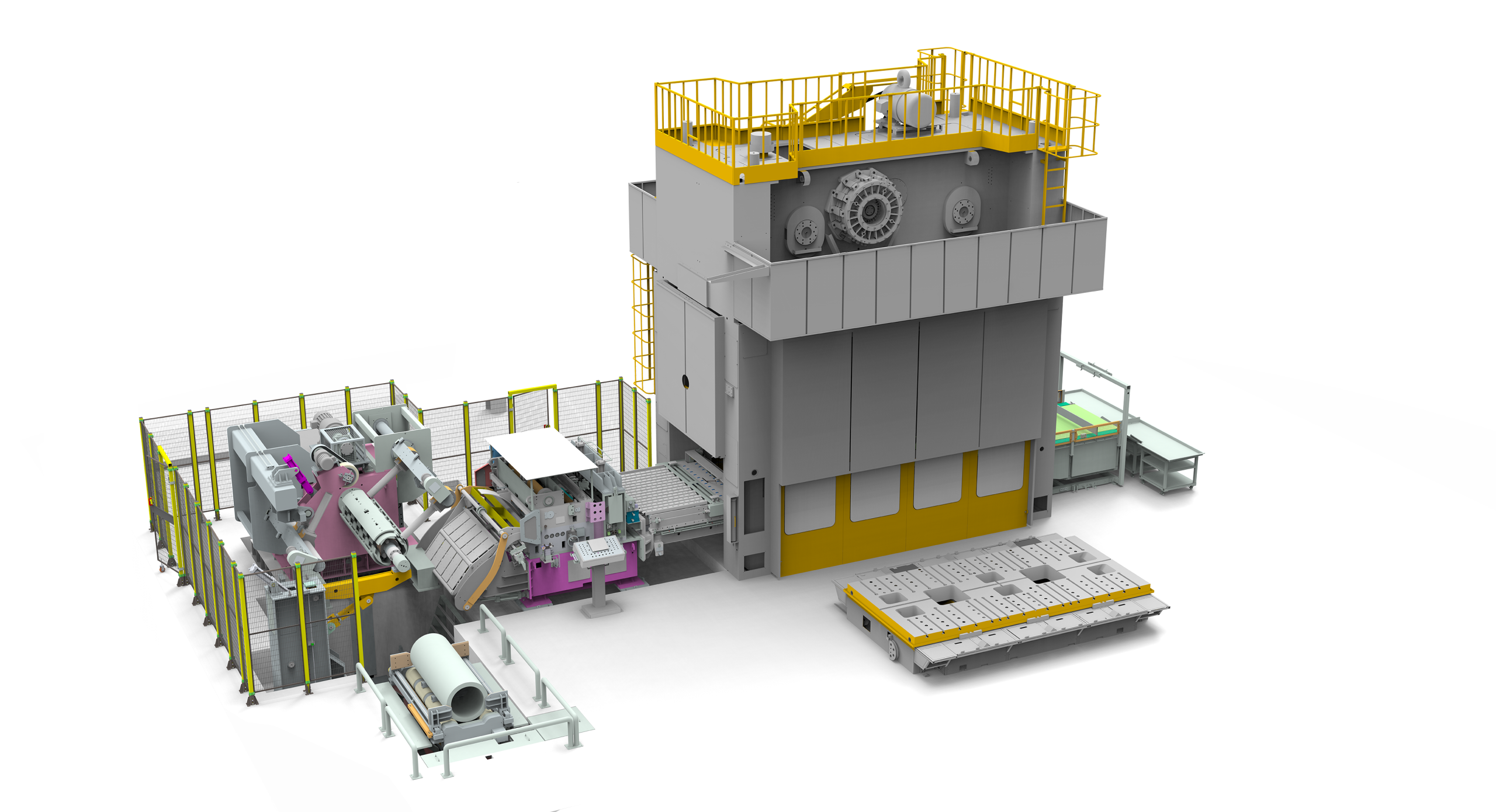

Fully Automatic High-Strength Continuous Stamping Line

Fully Automatic High-Strength Continuous Stamping Line Category: Blanking Line Coil Width: 200-1600mm Coil Thickness: 0.6-6.0mm Line Speed: 30m/min Max Production TAKT: 60SPM Max Material Strength:

.png)