What is a punch?

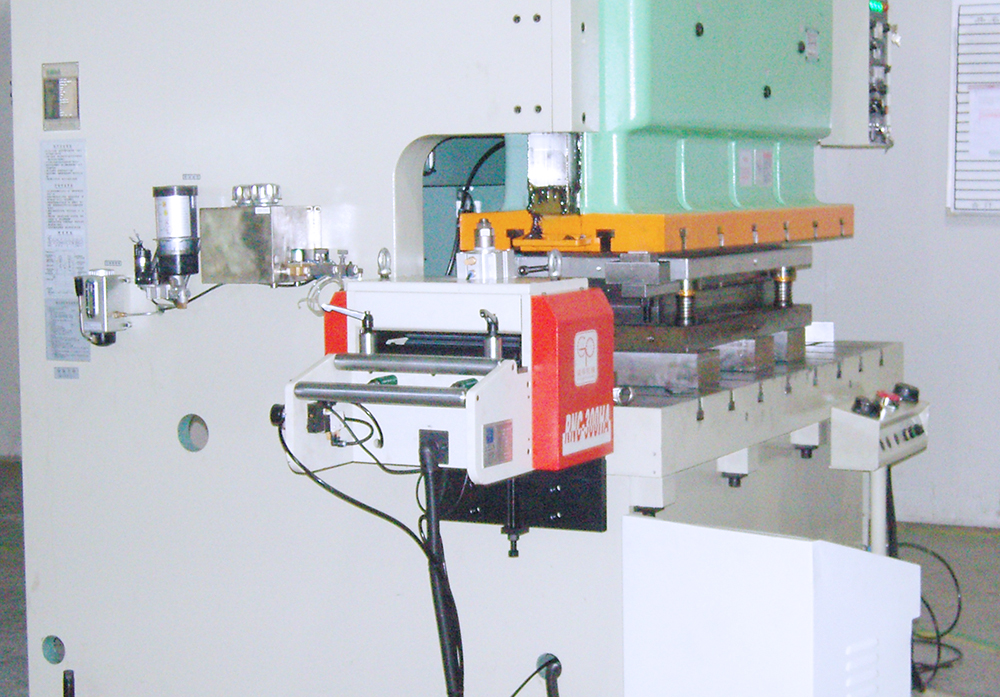

The punch servo feeder is a high-efficiency equipment to assist the punch feeding and is widely used in light and heavy industries. The traditional stamping production using punching machine is to match the punching machine with a single die and use manual manual feeding to complete the entire processing and production. We will come first. Let me first understand what a punch is. A punch press is a punching press, also known as a forming press. They are designed for blanking, punching, forming, deep drawing, trimming, fine blanking, shaping, riveting and extruding under hydraulic pressure. Widely used in electronics, communications, computers, household appliances, furniture, transportation, (automobiles, motorcycles, bicycles) hardware parts and other stamping and forming.

What are the benefits of a punch servo feeder?

Compared with the past, stamping owners did not have much demand for finished products, and did not require high precision. Today’s stamping production is developing towards high efficiency, high precision and high volume, and in order to meet the market demands and rise of different industries and machine tools, they must be flexible. Therefore, using automated equipment with punch presses to achieve fully automated stamping production, the type of equipment that feeds punch presses is one of the most important and profitable ways to improve productivity and help companies achieve their goals. It can fundamentally improve the production efficiency and core competitiveness of stamping enterprises. Compared with the traditional use of punching sheets, the problem of manual feeding has become increasingly prominent.

● Higher accuracy and longer life

The punch servo feeder features efficient operation that can significantly help the punch press produce more consistent parts. The punch servo feeder has an ideal positioning accuracy of 0.05mm or less, and this feature also extends the tool life of the punch. In addition, the continuous high-precision feeding process enables the machine to reduce the risk of wrong-spec products and the loss of scrap. The cost of the coil is much lower than that of the sheet, and the stamping waste is wound up by the subsequent rewinding equipment, which can be used to the greatest extent, which can improve the quality while reducing the production cost and improving the market competitiveness of stamping enterprises. .

● higher efficiency

The production efficiency of the automatic punching production line is often several hundred times that of the manual punching, and the accumulated error of each step is eliminated by a special relaxation device to ensure the consistent quality of the finished product.

● Security

The continuous die stamping production of the punch press uses a fully automated feeding operation, which fundamentally eliminates the occurrence of safety accidents: the automated production line of the punch press uses coil material, which can fully automatically realize uncoiling, leveling, and feeding. Fundamentally eliminates security risks.