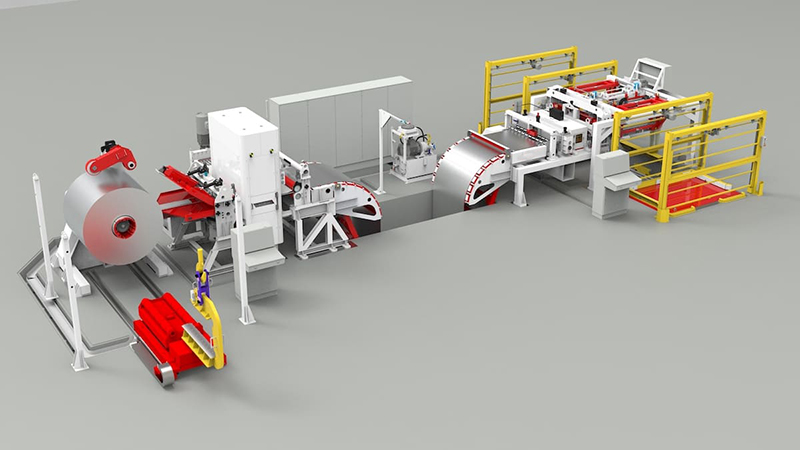

Ultimate Guide to Destacker Machines: Introduction, Applications, and Advantages

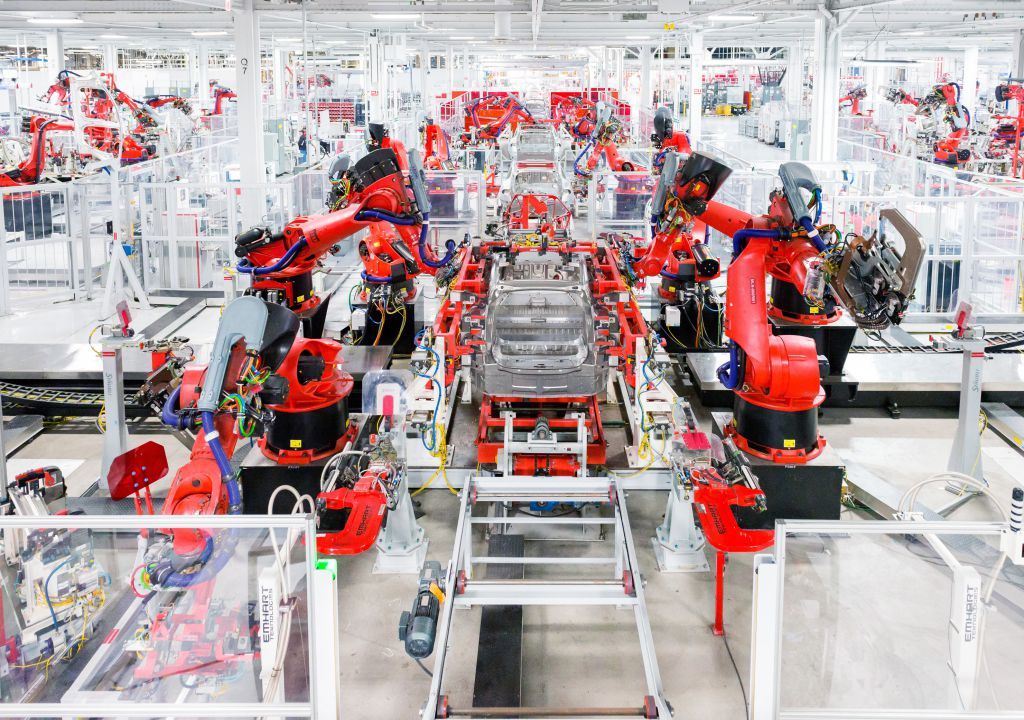

In the world of industrial automation, destacker machines stand as versatile workhorses that streamline the handling and processing of various products. This comprehensive guide serves as your gateway to understanding destacker machines, covering their introduction, applications, advantages, and more. Whether you’re a manufacturer or simply curious about automation technology, this guide has you covered. Table of Contents Introduction to Destacker