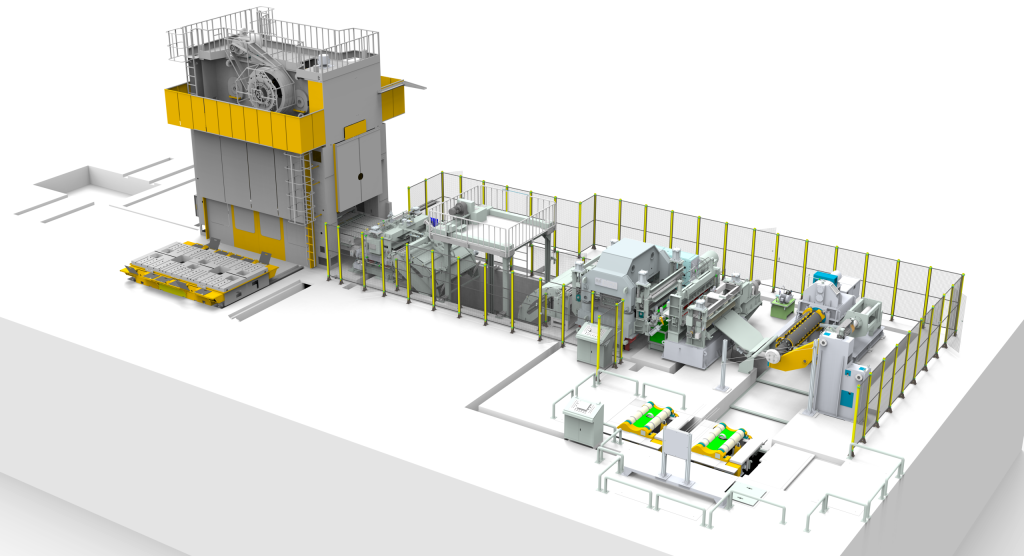

High-Speed Precision Blanking Line

High-Speed Precision Blanking Line Category: Blanking Line Brand: RUIHUI Coil OD: Ф800-Ф1800mm Coil ID: Ф508/Ф610(One-time Expansion) Coil Width: 300-1850mm Coil Thickness: 0.5-3.2mm Max Material Strength: 1180MPa(Tensile Strength) Max Production Speed: 70SPM Email Inquire Linkedin Facebook Youtube Introduction High-speed blanking line is a type of plate processing production line suitable for industries such as automotive and […]

Large Coil Tipper Machine

Large Coil Tipper Machine Category: Auxiliary Equipment Brand: RUIHUI Stack Length: 300-4500mm Stack Width: 300-2050mm Stack Height: 750mm(Including Tray) Stack Weight: 20T Rack Thickness: 150mm Maximum Opening: 300-1100mm Email Inquire Linkedin Facebook Youtube Introduction The large coil tipper machine is composed of the tipper part and the loading and unloading part, featuring both stack flipping and horizontal […]

Gravity Non-Deceleration Stacking System

Gravity Non-Deceleration Stacking System Category: Auxiliary Equipment Brand: RUIHUI Stack Switching: Without Stopping Stack Width: 300-1800mm Stack Length: 150-2000mm Stack Thickness: 0.5-3.2mm Email Inquire Linkedin Facebook Youtube Introduction The gravity non-deceleration stacking system utilizes the principle of gravity to achieve efficient and stable material stacking. After processing by the press, blanks are transferred to the […]

Robobeam Stamping Line

-1024x572.png)

Robobeam Stamping Line Category: Tandem Line Brand: RUIHUI Sheet Thickness: 0.5-3.2mm Max Sheet Width: 400*2500mm Min Sheet Width: 200*1500mm Production Material: Steel/Aluminum Email Inquire Linkedin Facebook Youtube Introduction The robobeam stamping line automates the entire process from destacking, loading, stamping, to unloading, minimizing manual intervention, reducing labor intensity and workforce costs, while enhancing production […]

Magnetic Blank Stacking System

Magnetic Blank Stacking System Category: Auxiliary Equipment Brand: RUIHUI Stack Weight: 10T Stack Length: 300-4500mm Stack Width: 300-2050mm Stack Height: 750mm(Including Tray) Email Inquire Linkedin Facebook Youtube Introduction The magnetic stacking machine will transport the material sheets, after being sheared by the blanking die, to the stacking area and stacking position via a magnetic conveyor […]

Kazakhstan Machinery Fair 2025

Ruihui is excited to announce our participation in the Kazakhstan Machinery Fair 2025, the premier event for the machinery and metalworking industries in Kazakhstan and Central Asia. At this event, RUIHUI will showcase our latest innovations in metal processing and stamping automation. Venue: Astana, EXPO IEC Dates: April 23-25, 2025 Booth: Stand E16.4 We warmly welcome […]

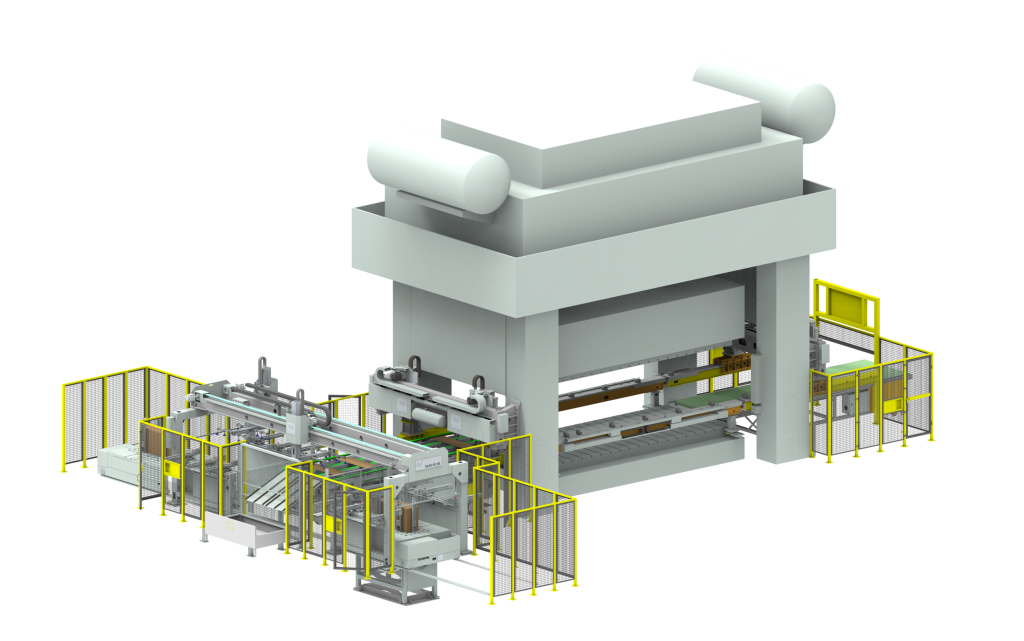

3-Axis Transfer Tandem Stamping Line

3-Axis Transfer Tandem Stamping Line Category: Tandem Line Max Sheet Width: 1800*1200mm Min Sheet Width: 400*150mm Feeding Stroke(X-Axis): 0-1500mm Clamping Stroke(Y-Axis): 0-300mm Lifting Stroke(Z-Axis): 0-300mm Email Inquire Linkedin Facebook Youtube Introduction The 3-axis transfer tandem stamping line integrates 3-axis transfer systems with multiple presses, supporting six stamping modes to flexibly handle multi-variety and small-batch production. […]

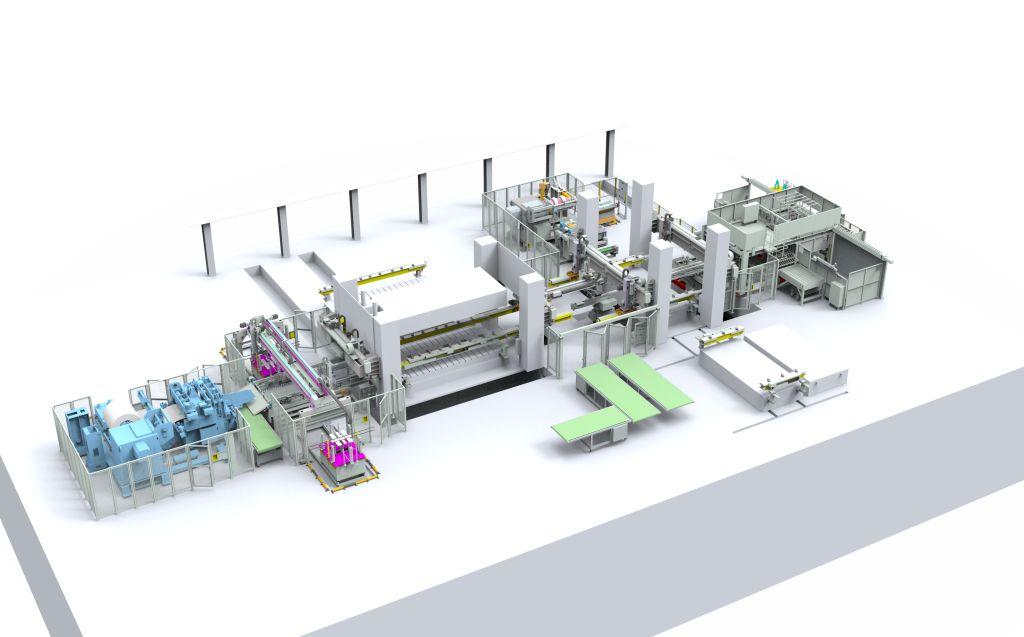

Truss Destacker 3-Axis Transfer Stamping Line

Truss Destacker 3-Axis Transfer Stamping Line Category: Destacker and Transfer/Blanking Line Max Sheet Width: 1800*1200mm Min Sheet Width: 400*150mm Sheet Thickness: 0.5-3.2mm Production Material: Steel/Aluminum Feeding Stroke(X-Axis): 0-1500mm Clamping Stroke(Y-Axis): 0-300mm Lifting Stroke(Z-Axis): 0-300mm Email Inquire Linkedin Facebook Youtube Product Introduction The truss destacker 3-axis transfer stamping line handles the destacking and conveying of both […]

Gravity Deceleration Stacking System

Gravity Deceleration Stacking System Category: Auxiliary Equipment Brand: RUIHUI Stack Switching: Stopping Stack Length: 150-2000mm Stack Width: 300-1800mm Stack Thickness: 0.5-3.2mm Email Inquire Linkedin Facebook Youtube Introduction The gravity deceleration stacking system is mainly used to receive individual material sheets conveyed out from the finished product conveyor system, enabling products to be neatly and orderly […]

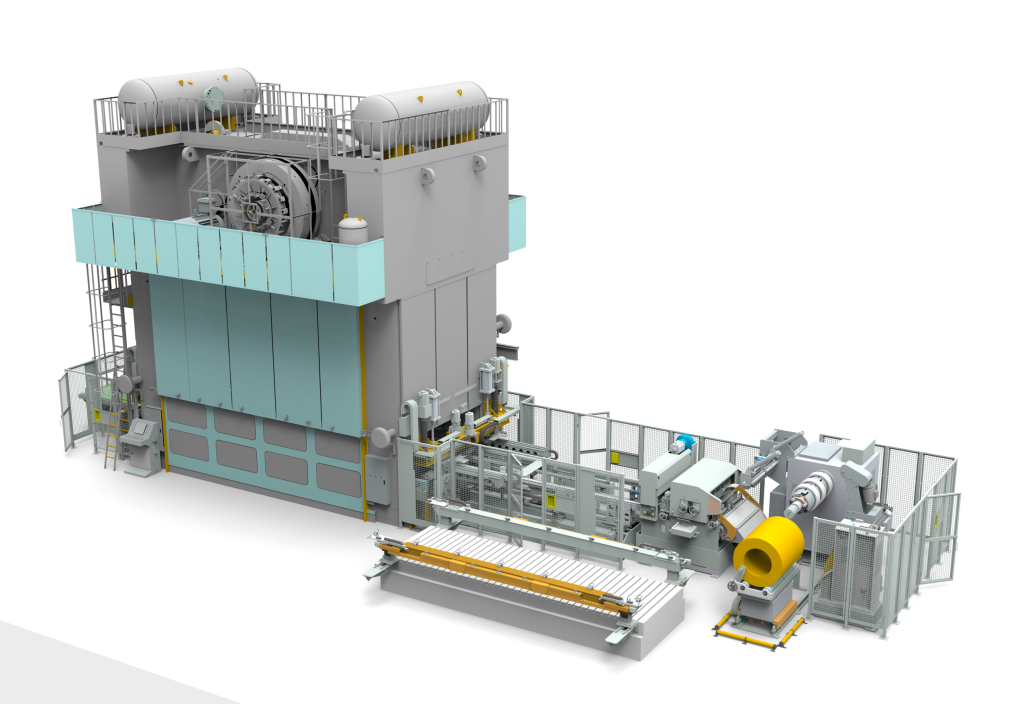

Fully Automatic 3-Axis Transfer Stamping Line

Fully Automatic 3-Axis Transfer Stamping Line Category: Transfer/Blanking Line Brand: RUIHUI Coil Width: 200-1300mm Coil Thickness: 0.6-6.0mm Matching Press Tonnage: 1000T-3500T Line Speed: 16m/min Max Material Strength: 490MPa(Tensile Strength) Shearing Speed: 25SPM Email Inquire Linkedin Facebook Youtube Introduction The fully automatic 3-axis transfer stamping line integrates multiple functional modules such as uncoiling, leveling and feeding, […]