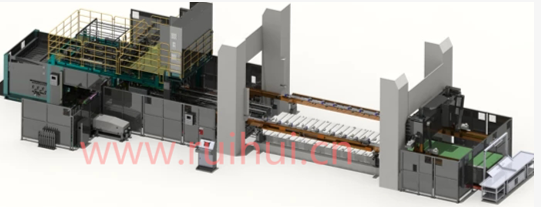

In the process of continuous pursuit of high efficiency, precision and intelligence in modern manufacturing, multi-station robots are playing an increasingly important role as key automation equipment. Guangdong Ruihui Intelligent Technology Co., Ltd. has been deeply involved in the field of intelligent technology and has made remarkable achievements in the research and development and application of multi-station robots. This article will introduce the professional knowledge of multi-station robots in detail.

I. Definition and Structure of Multi-station robotic arm for Stamping Automation

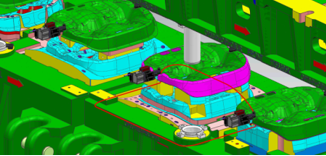

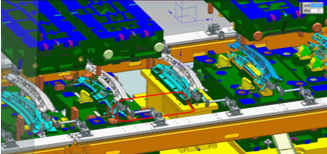

A multi-station robotic arm is an automated device that can imitate the movements of the human hand and automatically transport and operate workpieces between multiple stations according to a preset program. It usually consists of a mechanical body, a drive system, a control system, and a sensing system. The mechanical body is the actuator of the manipulator, responsible for completing the grasping, handling and other actions; the drive system provides power for the manipulator, and the common ones are pneumatic, hydraulic, and electric drives; the control system is the “brain” of the manipulator, which controls the movement trajectory and action sequence of the manipulator through programming instructions; the sensing system is used to monitor the working status of the manipulator in real time to ensure its safe and stable operation. For the specific operation process, please refer to the following video.

II. Advantages of Multi-station robotic arm

Advantages of the production line: We have a professional engineering and technical team for multi-station manipulators, adopting 3D modular design and 3D motion simulation analysis. Our company also implements the ERP information management system. Up to now, we have delivered more than 50 sets of multi-station manipulators, and the annual delivery quantity increases by more than 20 sets. With a large amount of on-site experience, we can better manufacture automation equipment that meets the needs of customers. In contrast to domestic counterparts, they have fewer designers and merely engage in simple plagiarism and imitation. They can only produce equipment with small tonnage and relatively low technical requirements. Moreover, they don’t have a complete material management system within their companies, and there is no complete management process for production materials, which invisibly increases the procurement costs for customers.

Advantages of the unstacking arm: Both the transverse movement and lifting of the unstacking and picking arm are driven by servo motors, which greatly improves the stability and intelligent control of the picking arm. The unstacking arm can choose one or two arms to work according to the requirements of the production cycle, ensuring stable and efficient production. With various unstacking mechanism modes, it can more effectively provide customers with the most suitable equipment solutions. The servo motor control systems all use well-known foreign brands, providing a strong guarantee for efficient, stable and safe production. However, most domestic counterparts have a single product range and cannot meet various customer needs.

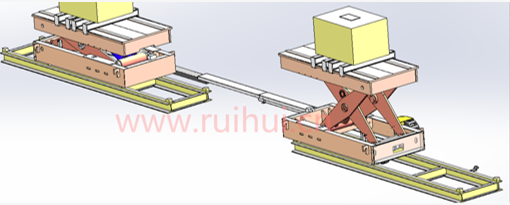

Advantages of the stacking trolley: It adopts double trolleys for alternate feeding and automatic switching, enabling the whole production line to operate without shutdown. It is hydraulically driven, with automatic lifting of the stack and quick adjustment of the magnetic separator. With various stacking trolley modes, it can more effectively provide customers with the most suitable equipment solutions. In contrast, most counterparts’ stacking trolleys have a single structure, are clumsy, and have a low degree of automation.

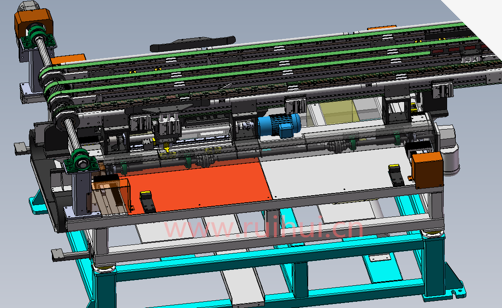

Advantages of the sheet conveyor: According to the characteristics of customers’ products, we recommend the best sheet conveying mechanism for customers, including the magnetic sheet conveying mechanism and the shuttle pallet sheet conveying mechanism. The diversification of magnetic belts can meet the production requirements for different sheet sizes. The belt mechanism is equipped with an automatic sheet positioning mechanism to pat and position the sheet, ensuring it can accurately enter the production mold cavity. It can automatically adjust the position and height of the “0” station, with a high degree of automation. Parameters can be retrieved with one click, eliminating the need for manual operation.

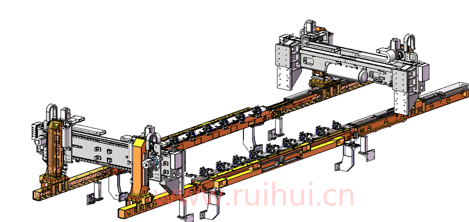

Advantages of the three-dimensional multi-station robotic arm: It is a manipulator with six-axis degrees of freedom and high flexibility. All six-axis transmissions are driven by servo motors, with planetary reducers + rack and pinion transmissions, ensuring stable transmission and high precision. It operates at the same angle as the press. During each stamping cycle of the automation system, it will compare the angle with the press more than four times to ensure the safety signal interlock between the automation system and the press during operation. It operates stably, and the production cycle of the whole line can reach 25 times per minute, which is beyond the reach of most domestic counterparts.

Advantages of the manipulator handling crossbeam: There are various choices of handling crossbeams. According to the parameters of different presses ordered by customers, production cycle requirements, etc., we can provide customers with the best handling crossbeam solutions. For large presses with side openings and extra-large worktables, by drawing on the technologies of Europe, America and Japan, we have overcome the problem of shaking during the conveying process of the handling crossbeam. We use a steel-aluminum hybrid handling crossbeam, which greatly reduces the moving weight of the crossbeam on the X-axis, significantly increases the load-bearing capacity of the crossbeam, and enables the handling gripper to stably clamp and place sheet materials, improving the stability during high-speed production. When domestic counterparts face the worktables of large presses (with a length of more than 6 meters), they adopt the overall crossbeam movement mode, which increases the moving weight on the X-axis. In order to meet the specific production cycle, the overall movement of the X-axis crossbeam has to increase the power and quantity of servo motors, resulting in increased costs for customers. The overall movement of the crossbeam leads to increased shaking during handling, reduced load-bearing capacity of the crossbeam, and a slower production cycle.

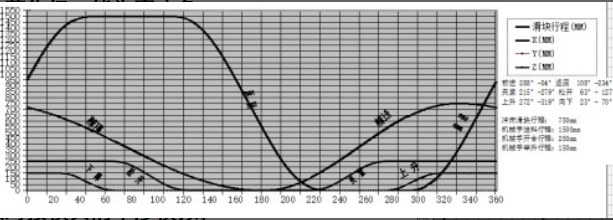

Advantages of the mold interference motion curve: We have the software copyright for the interference motion curve, and can provide customers with free simulation of the interference motion curves for the development of several new molds. We can provide free training on mold interference simulation inspection for customers and mold suppliers, helping customers fully understand the development and application of automated molds. We have a professional and mature team to deal with mold interference simulation, and can assist customers in conducting motion simulations and provide guidance on mold modification.

Advantages of production capacity: We have a complete set of production capabilities covering processes such as process planning, blanking, welding, machining, sandblasting, painting, assembly, and inspection, ensuring strict control over the quality of each process.