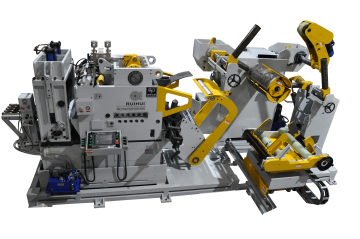

The maximum width of the corresponding material is 600~ 1300mm and the thickness is 6.0mm. The use of 11 working rollers improves the leveling reliability, makes the thin plate~ medium plate extremely flat, and the strengthening of the frame rigidity makes it possible to correct high strength. It can correspond to high-precision, high-speed punching machines. The large-angle opening mechanism can easily clean and maintain the rollers. In order to improve the stamping efficiency and productivity of thin plate~ medium plate, the latest model MAC4-F series was born.

Open working roller mechanism: The variable mandrel at the outlet can be opened up to 20 degrees. The large opening makes the cleaning of the roller very easy. The internal structure is clear at a glance, and the inspection and maintenance in the depths of the mechanism are more convenient.

Roll head flattening device streamlines operations, requiring minimal force from operators, which reduces labor fatigue and enhances safety. It precisely flattens the roll’s front end, eliminating irregularities. This smooth surface enables materials, like metal sheets or fabric rolls, to enter the roller easily, boosting production efficiency and output quality.

There are relevant videos below, through which you can learn more about the motion paths of each part in the process of unwinding, leveling, and feeding: