What are a heavy material rack and Lightweight Material Rack? What are the characteristics of each of these two material racks? Today we will compare and analyze them together.

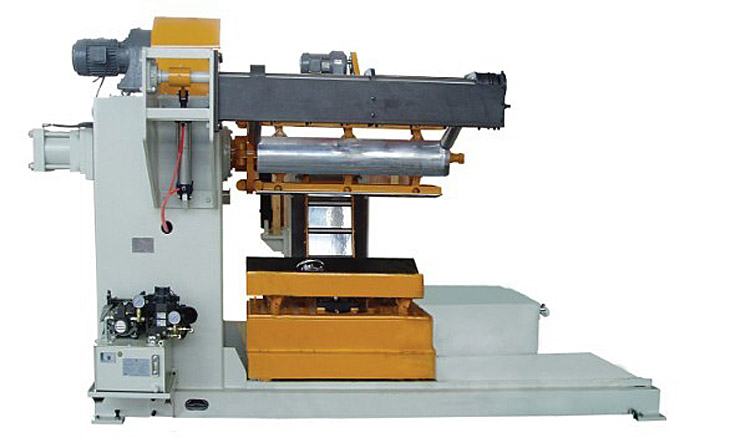

The heavy-duty material rack is a special piece of equipment for uncoiling metal coils. It is mainly used to carry metal coils in stamping industry automation. It can also be used for metal coils in different industries such as metal coil slitting lines and factory metal tile forming lines.

Features of Heavy Duty Material Rack:

1. The heavy-duty material rack is suitable for feeding various coil materials;

2. It can be used together with the straightening machine, and the unpowered type can be selected;

3. The larger load can be customized to 30 tons;

4. Larger material width can be customized to 1800 mm.

5. The heavy-duty material rack adopts imported electromagnetic contactors and electronic components, with fewer failures and long service life.

6. It is suitable for the delivery of various coil materials, both sheet metal and non-metal materials.

7. Motor power can be added to match the feeding device.

8. The tension of the braking device can be adjusted, and the main shaft adopts a reinforced type to make the material roll rotate more smoothly and increase its load force.

9. Welded by high-quality steel plates, the overall body has good strength and adopts long-distance bearing support points.

Features of Lightweight Material Racks:

1. The light material frame is divided into two forms: metal rod conduction and electronic fretting. Metal rod conductive induction: suitable for continuous stamping processing of various hardware and electronic parts. Electronic micro-motion induction: suitable for continuous stamping of various metals and non-metals.

2. The light material frame has a simple structure and a low failure rate.