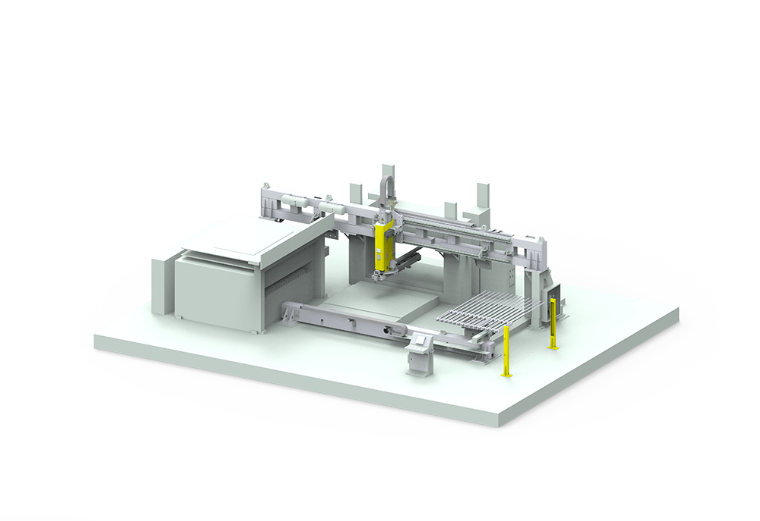

The Hot Stamping Process Test Line is an integrated test system that combines various equipment and technologies to simulate and analyze the entire hot forming production process under controlled conditions.

The Main Goal of hot forming process inspection line

The main goal of this product is to evaluate the properties of the material during the hot forming process, verify the feasibility of the forming process, and ensure the quality and consistency of the final hot forming product. Help manufacturers improve production efficiency, reduce costs and improve production quality.

Main components

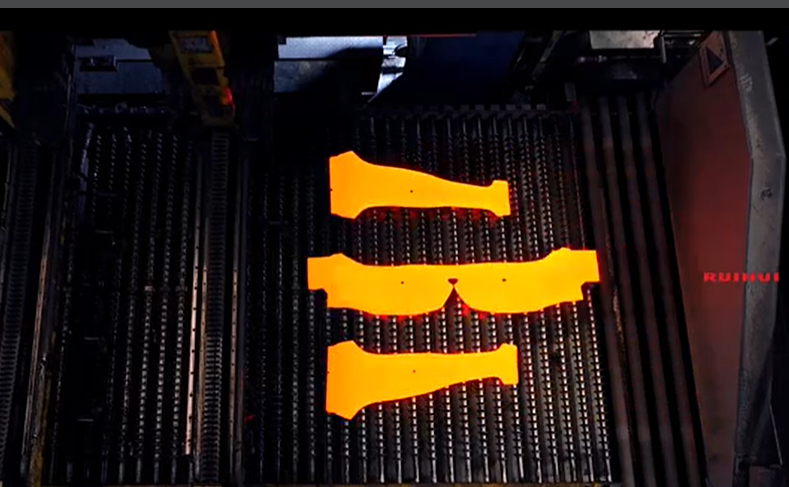

Heating Furnace:In the hot forming process testing line, the heating furnace is a crucial part, its role is to heat the raw materials to a temperature suitable for hot forming . The heating furnace can simulate the heating conditions in the actual production process, so that the workpiece is heated in an environment close to the real production, so as to accurately test the performance changes of the material during the hot forming process. By adjusting the heating speed, holding time and heating temperature of the heating furnace, the influence of different process conditions on the hot forming quality can be studied, and then the hot forming process parameters can be optimized to improve product quality and production efficiency.

Transfer Carry:In the hot forming process test line, the manipulator handling also plays a crucial role. The manipulator will first move to the raw material storage area, and accurately find the raw materials to be transported, such as metal billets, through the visual recognition system or preset location information. Use the gripping tool to firmly grasp the raw materials, and carry the raw materials to the feeding port of the heating furnace according to the pre-planned path, and then accurately place them in the designated position in the heating furnace.

Blank Fork:The material fork is a commonly used material handling tool, mainly used for forking, moving and placing the blank or workpiece. When the material fork is close to the blank, through the operation of the handling equipment, the fork body is inserted into a suitable position below the blank. During the insertion process, it is necessary to ensure that the contact area between the fork body and the blank is large enough to ensure the stability of the forking. If it is a material fork with a driving mechanism, the fork body can be raised by controlling the driving mechanism to lift the blank from the placement surface. After forking the blank, the handling equipment moves the material fork and the blank together to the target position according to a predetermined path. During the handling process, it is necessary to maintain the stability and level of the material fork to avoid shaking or falling of the blank. After reaching the target position, the fork body is lowered by the handling equipment or the driving mechanism, and the blank is placed at the designated position. Then, the fork body is pulled out from under the blank to complete a handling operation.

Features and advantages

| Maximum material size (mm): | 1800*1500mm |

| Minimum material size (mm): | 400*150mm |

| Material thickness (mm): | 0.6-3.5mm |

| Number of pieces produced: | 1 mold 1 piece |

| Material: | Steel/Aluminum |

| Suitable furnace types: | Continuous furnace |

| Material weight: | ≤30KG |

| Configuration system: | Siemens control system and drive system |

- High efficiency: The automatic production line realizes continuous production without stopping the machine to change the mold, which greatly improves the production efficiency. The automatic feeding system and conveyor system operate efficiently, saving manpower and time costs.

- Accuracy: The automatic control system can precisely control the parameters of each process to ensure the consistency of product size and quality. Eliminate errors and fluctuations in manual operation and improve product accuracy and stability.

- Flexibility: The production line can be quickly adjusted and switched according to the requirements of different products to meet the production needs of multiple varieties and small batches. By changing molds and adjusting parameters, the production line can easily cope with the processing requirements of different products and reduce product conversion time.

- Safety: Automated production reduces the chance of workers coming into contact with machines and reduces the risk of personal injury during production. Systematic safety measures and emergency stop functions ensure the safe operation of the production process.

- Cost saving: Automated production reduces labor costs and human resource investment. By precisely controlling material and energy consumption, waste rate and energy waste are reduced, and production costs are saved.

- Data monitoring and analysis: The automatic control system can monitor the data in the production process in real time and record the production situation. Through data analytics, potential problems can be identified in time, production processes can be optimized, and production efficiency and product quality can be improved.

The advantages of Guangdong Ruihui Intelligent Technology Co., Ltd.

Guangdong Ruihui Intelligent Technology Co., Ltd. has unique advantages in the research and development, production and sales of hot forming process inspection lines. The company has a research and development team composed of senior engineers, with profound technical accumulation and innovation ability, and can provide customized solutions according to different needs of customers. In addition, the company strictly follows the international quality management system to ensure that the quality and performance of products reach the international advanced level. In terms of after-sales service, Guangdong Ruihui Intelligent Technology Co., Ltd. has established a global service network, which can respond to customer needs in a timely manner and provide customers with all-round technical support and maintenance services.