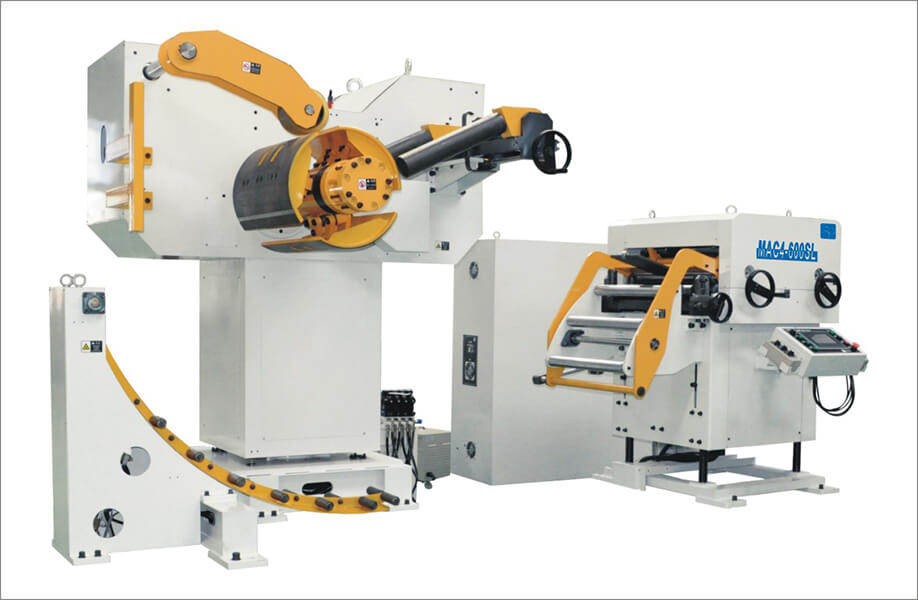

The 3-in-1 feeder is a type of machine that is designed to automatically lead and feed materials during a manufacturing or production process. This type of feeder is called a 3-in-1 feeder because it performs three functions in one machine: material loading, material conveying, and material feeding. The 3-in-1 feeder is a versatile and efficient tool that can greatly improve the speed and accuracy of a manufacturing process, as it eliminates the need for manual material handling and reduces the risk of human error.

When the demand for uncoiling, the rotating cylinder is initiated, the rotating cylinder rotates the power shaft through the chain, the power shaft rotates all the material racks, and the rolled material is initially transported, and the transported rolled material is folded and flattened by the pallet equipment and collaborated into the material guiding arrangement, and enters into the leveling arrangement, which ends the automatic material guiding and feeding.

Subsequently, the strip material entering the leveling arrangement is guided by the lower feeding guide plate and the upper feeding guide plate into the lower feeding roller and the upper feeding roller.

Since the lower leveling roller of the machine is rotating and the upper leveling roller can be dispatched independently, it can better eliminate the curvature and stress of the strip material under the action of the upper and lower leveling rollers, advance the leveling quality and facilitate the subsequent process; since the interval of the adjacent lower leveling rollers is different and the interval of the adjacent upper leveling rollers is different so that the strip material can be coarsely shaped in the front part and finely shaped in the back part. shaping, and then advancing the quality of leveling.

There are many different types of 3-in-1 feeders on the market, each designed for a specific type of material and production process. Some common types of 3-in-1 feeders include vibratory feeders, belt feeders, and screw feeders. A vibratory feeder uses vibrating motion to move material along a conveyor belt, while a belt feeder uses a continuous belt to transport material. Screw feeders use a rotating screw to move material through a trough or tube.

Another benefit of using a 3-in-1 feeder is the ability to handle a wide variety of materials. These feeders can be customized to handle materials of different sizes, shapes and textures, making them suitable for a variety of industries and production processes. For example, a 3-in-1 feeder can be used in the automotive industry to dispense parts, or in the food industry to dispense ingredients for processing and packaging.

Overall, the 3-in-1 feeder is an invaluable tool for automating material handling processes in a manufacturing or production environment. By eliminating the need for manual labor and reducing the risk of human error, these feeders can greatly increase the efficiency and accuracy of the production process. Furthermore, their versatility and flexibility make them suitable for a wide range of industries and applications, making them an essential part of many modern production lines.